Language

Views: 0 Author: Site Editor Publish Time: 2025-12-08 Origin: Site

You find N52 neodymium magnets in many modern devices. They have strong magnetic force in a small size. N52 magnets are about 20% stronger than N42 magnets. They are over 50% stronger than N35 magnets. N52 is the strongest grade you can get. These magnets are great for jobs needing high magnetic power. Makers use new ways and special coatings to make them last longer. The coatings help stop rust. TAIXIONG gives dependable neodymium magnets to industries. These industries want better and smarter solutions.

N52 neodymium magnets are the strongest you can get. They have a lot of magnetic power in a small size. This makes them great for many uses.

Pick the right coating for your N52 magnets. The coating helps them last longer and keeps them from getting rusty. This is very important if you use them in tough places.

Think about what your project needs before you choose neodymium magnets. Look at things like size, shape, and how much heat they can take.

TAIXIONG can make special magnets just for you. You can pick the best magnet for your job. This makes sure the magnet works well and is dependable.

Be careful when you use N52 magnets so you do not get hurt. Store them the right way to keep them strong and make them last longer.

You often see n52 neodymium magnets in places where you need the strongest magnetic force. The N52 grade means the magnet has a maximum energy product of 52 MGOe. This number shows how much magnetic strength the magnet can deliver. The grading system uses the letter "N" and a number. Higher numbers mean stronger magnets. N52 neodymium magnets stand at the top of this scale. You get more power in a smaller size. TAIXIONG supplies high-performance neodymium magnets to industries that need reliable solutions. You can trust TAIXIONG for quality and innovation.

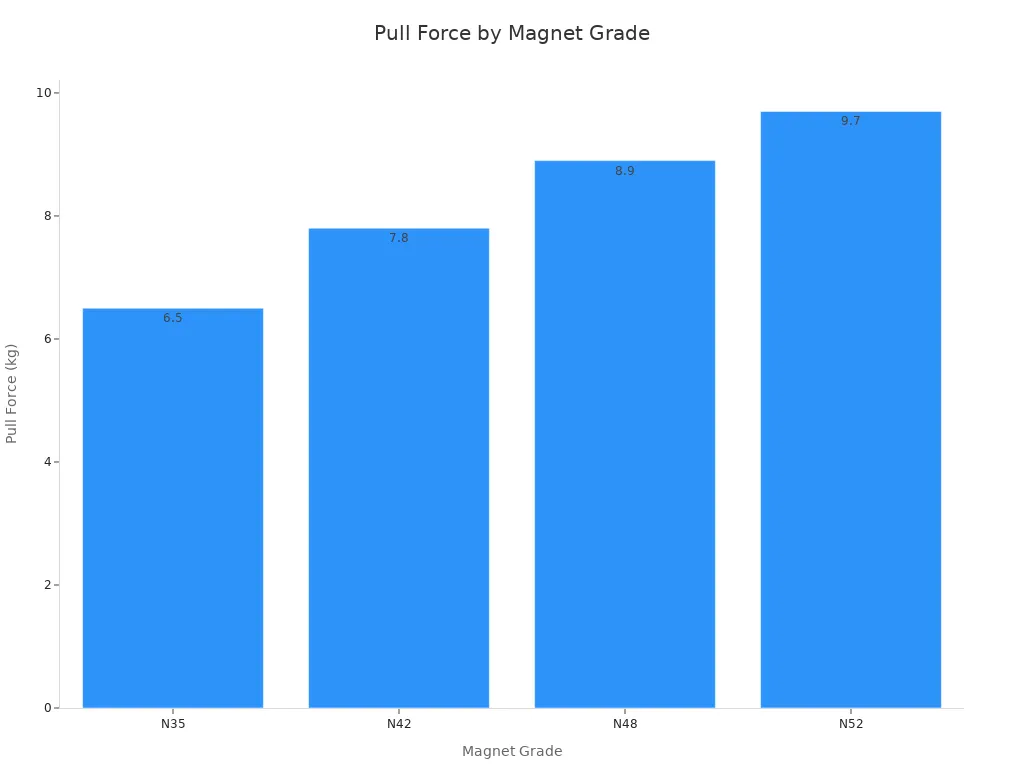

Neodymium magnets use a mix of neodymium, iron, and boron. The N52 grade keeps the same basic formula as other grades but gives you more strength. You can see how the composition compares in the table below:

| Magnet Grade | Neodymium (%) | Iron (%) | Boron (%) | Pull Force (kg) |

|---|---|---|---|---|

| N35 | 31-32 | 64-65 | 1 | ~6.5 |

| N42 | 31-32 | 64-65 | 1 | ~7.8 |

| N48 | 31-32 | 64-65 | 1 | ~8.9 |

| N52 | 31-32 | 64-65 | 1 | ~9.7 |

You notice that as the grade goes up, the pull force gets stronger. The N52 grade gives you the highest pull force among neodymium magnets.

You choose n52 neodymium magnets when you need a strong rare-earth magnet in a compact space. These magnets work well in electronics, motors, and medical devices. You get more magnetic field strength than lower grades like N35. You can use smaller magnets without losing power. Industries pick N52 neodymium magnets for demanding jobs. You benefit from advanced manufacturing and rare materials. TAIXIONG offers custom solutions so you get the right magnet for your needs. You can rely on their expertise for high-power applications.

N52 neodymium magnets are very strong. They have the highest magnetic strength of all neodymium grades. The maximum energy product, called BHmax, tells you how much magnetic energy a magnet can hold. You can look at the table below to see the difference:

| Magnet Grade | Maximum Energy Product (BHmax) (MGOe) |

|---|---|

| N30 | 28-30 |

| N33 | 31-33 |

| N35 | 33-35 |

| N38 | 36-38 |

| N40 | 38-40 |

| N42 | 40-42 |

| N45 | 43-45 |

| N48 | 45-48 |

| N50 | 47-51 |

| N52 | 48-53 |

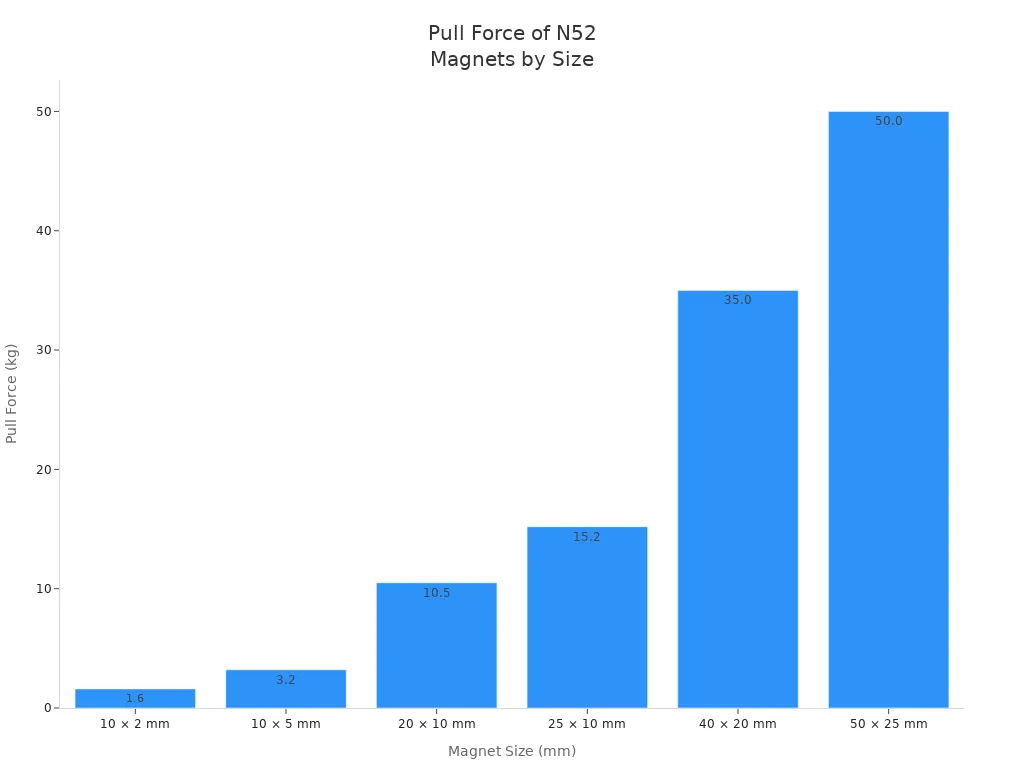

N52 neodymium magnets give more pull force, even when they are small. For example, a 10 × 2 mm magnet can lift about 1.6 kg. A 50 × 25 mm magnet can lift up to 50 kg. The chart below shows how pull force goes up as the magnet gets bigger:

You can use these magnets in many places. They work well in motors, sensors, and industrial tools.

Neodymium magnets need protection to stay strong. You can pick from different coatings to help your magnets last longer. Each coating has its own benefits:

| Coating Type | Properties and Benefits | Suitable Applications |

|---|---|---|

| Nickel-Copper-Nickel (Ni-Cu-Ni) | Stops rust, looks shiny. | Motors, sensors, jewelry. |

| Zinc (Zn) | Fights rust, saves money. | Automotive sensors, general industrial use. |

| Epoxy | Blocks water and chemicals, comes in many colors. | Outdoor environments, wind turbines, marine. |

| Polytetrafluoroethylene (PTFE) | Stays safe from chemicals and rust, does not stick. | Medical devices, food processing equipment. |

| Gold (Au) | Does not tarnish or rust, looks nice. | Electronic applications, connectors. |

| Rubber | Absorbs shocks, stops chips, does not slip. | Consumer products, magnetic mounts, toys. |

Pick the coating that fits where you use the magnet. This keeps your magnet safe and strong.

Neodymium magnets can lose power if they get too hot. N52 neodymium magnets work best up to 60 ºC (140 ºF). If you use them in hotter places, they may get weaker. Always check the temperature before using these magnets in hot spots.

Tip: Keep your neodymium magnets in a cool, dry spot. This helps them stay strong for a long time.

N52 neodymium magnets are very strong for their size. You can use them in small spaces. These magnets work well in many devices. The table below shows why people pick N52 neodymium magnets:

| Advantage | Description |

|---|---|

| High Magnetic Strength | N52 magnets have the most strength of neodymium magnets. You can use smaller magnets for strong magnetic fields. |

| Space-Saving | Their power means you need less space. They fit well in small devices. |

| Versatility | You can use them in many areas, like machines and electronics. |

| Cost-Effective | They cost more at first, but you need fewer magnets. This helps save money. |

You see these magnets in motors, sensors, and speakers. Their strength means you use fewer magnets. You save space and money. Neodymium magnets work in cars and electronics. You can count on them to work well.

Neodymium magnets are very strong. You need to be careful when you use them. They can hurt you if you do not handle them right.

Permanent magnets can cause bad injuries if they snap together. The worst is crushing, which happens if your body gets caught between two magnets or a magnet and steel.

Here are some safety tips:

Keep magnets away from people with pacemakers or implants.

Wear gloves so you do not get pinched. Use spacers to pull magnets apart.

Always wear eye protection. Magnets can break because they are brittle.

Do not drill or grind magnets in places with bad airflow. The dust can catch fire.

Store magnets where it is not humid. This stops rust.

You can also do these things for extra safety:

Stay at least 300 mm away from magnets if you have implants.

Use tools that are not magnetic to move magnets.

Put magnets in containers that are not magnetic so they do not stick together.

Neodymium magnets are powerful. You must use them safely. Follow these rules to keep your workspace safe. If you use them the right way, you can make better devices.

Image Source: pexels

TAIXIONG is a top company in the neodymium magnet business. Their magnets are strong and can be used in many ways. TAIXIONG lets you pick magnets that fit your needs. Let’s see how neodymium magnets help different industries.

Neodymium magnets are in many things you use every day. They are small but very strong, which is good for electronics. Here are some ways neodymium magnets are used in devices:

Laptops use neodymium magnets to keep power connectors tight and slim.

Smartphone cases and mounts use strong magnets to hold things in place.

Headphones and speakers use neodymium magnets to move parts fast. This makes sound better.

Magnetic chargers and stands use these magnets to hold things steady.

Because of neodymium magnets, devices are lighter, thinner, and work better.

Neodymium magnets are used in cars and factories. Their strength helps make machines smaller and work better.

N52 magnets are used for latches, audio gear, MRI scanners, lifting heavy things, and sorting materials in recycling.

These magnets help you in many ways:

Motors can be smaller and lighter but still strong.

Small motors can have more power, so they work better.

Motor cases can be 20% smaller and still have the same power. This shows neodymium magnets are great for cars.

Neodymium magnets are also in lifting tools and machines that sort things. These tools help move heavy stuff and separate materials fast.

Neodymium magnets are important in medical and science tools. They are strong and work well for careful jobs.

MRI machines use neodymium magnets to make strong fields for clear pictures.

Magnetic therapy tools use these magnets to help with pain.

Surgeons use neodymium magnets in special devices for the stomach.

Doctors and scientists trust neodymium magnets for safe and good results.

TAIXIONG lets you pick the size, coating, and type of neodymium magnet you need. The table below shows some choices from TAIXIONG:

| Feature | Specification | Benefit |

|---|---|---|

| Material | Neodymium Magnet (N52) | Strong and lasts a long time |

| Coating | Gold, Nickel, Zinc, Epoxy | Stops rust and helps magnets last |

| Certification | RoHS | Safe for the environment |

| Tolerance | ±1% | Fits just right for important jobs |

| Size Options | 100 X 50 X 10 mm, 100 X 50 X 20 mm | Good for many uses |

You can work with TAIXIONG to get magnets that fit your project. Their team helps you pick the best magnet, shape, or coating. This makes sure you get the best results and value.

N52 magnets are used in many jobs. TAIXIONG’s neodymium magnets give you the strength and reliability you need to do well.

Image Source: pexels

You face many choices when you look at neodymium magnets. The grade tells you how strong the magnet is and how much you pay. N52 neodymium magnets give you the highest magnetic strength. You see a big difference when you compare them to other grades. The table below shows how N52 stands out:

| Grade | Maximum Energy Product (MGOe) | Relative Cost |

|---|---|---|

| N35 | 35 | $1.00 |

| N42 | 42 | $1.25 |

| N52 | 52 | $2.10 |

N52 neodymium magnets are much stronger than N35 and N42. You get more magnetic force in a smaller size. You pay more for N52, but you use fewer magnets for the same job. N35 magnets cost less and work better in high-heat places. You need to think about your budget and your project’s needs before making a selection.

Tip: Choose N52 neodymium magnets for jobs that need the most power in the smallest space. Pick lower grades if you want to save money or need magnets for hot environments.

You must look at size, shape, and magnetization when selecting the right neodymium magnet. Each factor changes how the magnet works in your project. The table below helps you see what matters:

| Factor | Description |

|---|---|

| Application Requirements | Decide how much magnetic field and strength you need. |

| Space Constraints | Pick a shape that fits your device or machine. |

| Magnetic Strength | Match the strength to your job and pick the best shape for it. |

| Temperature Resistance | Make sure the magnet can handle the heat in your workspace. |

| Cost | Check which shape gives you the best value for your money. |

You see neodymium magnets in many shapes. You find discs, blocks, rings, and arcs. Each shape fits a different job. You pick a disc for sensors. You use a block for holding tools. You choose a ring for motors. You also decide how the magnet is magnetized. Some magnets pull from the flat side. Others pull from the edge. You must match the magnetization to your project.

Note: Always measure your space before you order neodymium magnets. This helps you avoid mistakes and saves you time.

You need to protect neodymium magnets from rust and damage. The coating you pick changes how long your magnet lasts. You see big differences in harsh places like factories or near the ocean.

Coated neodymium magnets last 15-20 years in tough jobs. Uncoated magnets may fail in 3-5 years.

In salty air, uncoated magnets can break down in just 3 months.

Epoxy-coated magnets keep their surface 20 times better than bare magnets after salt tests.

Nickel-plated neodymium magnets keep up to 98% of their strength after 5 years.

Epoxy coatings last over 2,000 hours in salt spray tests.

Parylene coatings resist chemicals and add little thickness. Plastic coatings cost less for easy jobs.

Parylene costs more at first, but it can make magnets last 300% longer and save money over time.

You must match the coating to your workspace. Pick epoxy for wet or salty places. Use nickel for most jobs. Try parylene for chemical labs. Choose plastic for simple uses.

Tip: Always ask about coating options when selecting the right neodymium magnet. The right coating saves you money and trouble.

You want a supplier who gives you quality and service. TAIXIONG helps you with neodymium magnets for many industries. You see their strengths in the table below:

| Criteria | Description |

|---|---|

| Certification and Compliance | TAIXIONG meets ISO 9001, IATF 16949, and ISO 13485 standards. They use safe materials. |

| In-House Manufacturing Capabilities | TAIXIONG controls every step, from alloy making to coating. You get better quality. |

| Quality Assurance and Testing | TAIXIONG checks magnetic strength, size, and coating durability. You get reliable neodymium magnets. |

You get help with selection and custom orders. TAIXIONG offers many shapes, sizes, and coatings. You work with their team to pick the best neodymium magnets for your job. You trust their experience and their focus on quality.

Tip: Contact TAIXIONG for advice on selecting the right neodymium magnet. Their experts help you match grade, shape, and coating to your needs.

You make better choices when you know how to select neodymium magnets. You look at grade, size, shape, magnetization, coating, and supplier. You get the best results for your project when you use these steps.

You must store neodymium magnets carefully to keep them safe. If you do not store them right, they can lose power or break. Check the coating for any scratches or dull spots. Always put neodymium magnets in pairs or stacks with opposite poles together. Steel keepers help hold in the magnetic field and keep magnets strong. Keep the air dry, under 50% humidity, to stop rust. Be gentle when you handle neodymium magnets so they do not chip. Do not let magnets hit each other directly. Use thick boxes or cases for big neodymium magnets. Keep the temperature between 50°F and 85°F (10°C to 30°C). Store neodymium magnets in dry places to stop water damage. Check often for rust or coating problems.

| Storage Practice | Description |

|---|---|

| Check Coating for Damage | Look for scratches or exposed metal. |

| Store in Pairs or Stacks | Use opposite poles facing each other. |

| Use Steel Keepers | Contain the magnetic field. |

| Maintain Low Humidity | Keep below 50% to prevent corrosion. |

| Handle with Care | Prevent chipping during handling. |

| Avoid Direct Magnet Impacts | Stop damage from strong impacts. |

| Store in Secure Enclosures | Use thick containers for large magnets. |

| Control Temperature | Keep between 50°F and 85°F (10°C to 30°C). |

| Prevent Moisture Damage | Store in dry environments. |

| Regularly Check for Corrosion | Look for rust or coating damage. |

You can help neodymium magnets last longer by doing easy things. Wipe neodymium magnets with a dry cloth to clean them. Do not use water or harsh cleaners that can hurt the coating. Check neodymium magnets often for chips or cracks. If you see damage, replace the neodymium magnet to keep things safe. Pick the right coating for where you use the magnet. Nickel and epoxy coatings help stop rust on neodymium magnets. Store neodymium magnets away from heat and wet places. If you use neodymium magnets in machines, check them during regular checkups. This helps you find problems early and keeps neodymium magnets working well.

Tip: Wear gloves when you handle neodymium magnets. This keeps your fingers safe and protects the coating.

You can help nature by picking neodymium magnets made in better ways. Companies now try to make less pollution when making magnets. They work to lower harm to the earth. Mining neodymium can hurt land and water if not done right. Some companies use safer ways to protect animals and plants. They do not use illegal mining and control chemicals. Open-pit mining can ruin nature and make water dirty. You should buy neodymium magnets from companies that care about the planet. Recycling neodymium magnets also cuts down on waste. When you pick neodymium magnets from good sources, you help make cleaner products and safer recycling.

People are working to make neodymium magnets with less harm to nature.

Companies try to keep water clean and use fewer bad chemicals.

Recycling neodymium magnets saves resources and cuts pollution.

N52 neodymium magnets are very strong for their size. They fit well in motors and electronics. You can use them in big machines too. TAIXIONG follows important safety and quality rules like ISO9001 and SGS. This means you get magnets you can trust. You can ask for special neodymium magnets for your project. If you want more info or want to buy, you can talk to TAIXIONG for help.

| Key Strengths and Applications of N52 Neodymium Magnets |

|---|

| Stronger than lower grades, ideal for tough jobs |

| Small size, good for holding things and motors |

| Works in many places with different temperatures |

Ask TAIXIONG about magnet grades, shapes, and coatings.

Look at common questions before you buy.

N52 magnets have the most magnetic strength. They work well in tight spaces. You need fewer magnets to do the same job as weaker grades.

You can ask for special shapes, sizes, and coatings. TAIXIONG can use CNC machines and make different magnet patterns. This helps you get magnets that fit your project.

Tip: Use nickel for most jobs. Pick epoxy if it is wet. Choose zinc if you want to save money. Ask TAIXIONG if you are not sure which coating to use.

You must be careful with N52 magnets. They can pinch your fingers or hurt electronics. Always wear gloves and keep them away from medical devices.

| Application | Example Use |

|---|---|

| Electronics | Speakers, sensors |

| Automotive | Motors, latches |

| Medical | MRI, therapy tools |

| Industry | Lifting, sorting |

N52 magnets are used in many types of work.