Language

Views: 0 Author: Site Editor Publish Time: 2025-11-24 Origin: Site

When you pick a neodymium magnet, you need to think about its strength. This strength changes how well the magnet works for your project or job. Knowing the grade and measurement helps you pick the right neodymium magnet. Many people think size is the only thing that makes a magnet strong, but material, shape, and surface area are also important. Some people think magnets last forever or that stronger magnets are always better, but all magnets can lose strength and the best magnet depends on your task. Always be careful when you use strong magnets so you do not get hurt. TAIXIONG has many years of experience to help you make good choices and stay safe.

Learn about magnet strength by looking at pull force and gauss. This helps you pick the right magnet for your job.

Pick the neodymium magnet grade that fits your project. Higher grades like N52 are stronger for tough jobs.

Think about temperature and humidity when you use neodymium magnets. These things can change how strong the magnets are and how long they last.

Always follow safety rules when you use neodymium magnets. Wear gloves and safety glasses to stop injuries from strong pulls or if they break.

Ask experts like TAIXIONG for help picking the best magnet for your needs. Their advice can help you make good choices.

When you see a neodymium magnet, you might ask why it is strong. Magnet strength means how much force the magnet can make. This force lets the magnet hold, lift, or pull things. Scientists have two main ways to check this strength: surface magnetic field and pull force.

Surface magnetic field tells how strong the magnet is on its outside. You measure this in gauss or tesla.

Pull force shows how much weight the magnet can hold before it falls off. You measure this in pounds or kilograms.

You can use a gaussmeter or teslameter to test the magnetic field. A pull force gauge checks how much the magnet can hold.

Many things can change the strength, like the type of neodymium, size, shape, temperature, distance, and how you use it.

Here is a table to help you see the main ways to check neodymium magnet strength:

| Measurement Type | Description | Standard Units |

|---|---|---|

| Pull Force | The force needed to pull the magnet away from a surface. | Pounds |

| Flux Density | The strength of the magnetic field at a certain point near the magnet. | Gauss, Tesla |

You need to know these ways to compare neodymium magnets and pick the right one for your job.

The strength of a neodymium magnet can change how well it works for your project or business. If you pick a magnet that is too weak, it may not hold or pull things as you want. If you pick one that is too strong, it can cost more and might cause trouble with other machines.

If the neodymium magnet is not strong enough, it may not hold or pull things. This can waste time or even break things.

If the magnet is too strong, it can cost more and may mess up other parts or devices.

Handling strong neodymium magnets can be dangerous. You could get pinched if two magnets snap together fast. Strong magnets can also fly and break things or hurt people.

Many jobs need the right neodymium magnet strength to work well. Here is a table that shows how different jobs use neodymium magnets and why strength matters:

| Industry | Application Description |

|---|---|

| Healthcare | Neodymium magnets help MRI machines make clear pictures so doctors can find diseases. |

| Audio Equipment | These magnets help speakers turn electric signals into sounds you can hear. |

| Recycling | Magnetic separation uses neodymium magnets to sort things fast and well. |

| Robotics | Robots use strong magnets to move and work better. |

| Communication Technology | Radar and satellite devices need strong magnets to work right. |

Tip: Always pick the neodymium magnet strength that fits your job. This helps you get the best results and keeps you safe.

You will see neodymium magnet grades listed with an "N" and a number, such as N30 or N55. These numbers show how strong the magnet is and how much energy it can store. The higher the number, the stronger the magnet. You can use this system to compare different magnet grades and pick the right one for your needs.

The "N" stands for neodymium.

The number after "N" shows the maximum energy product (BHmax) of the magnet.

Higher numbers mean greater strength and energy density.

Most neodymium magnet grades range from N30 to N55.

Here is a table to help you see how the grades compare:

| Magnet Grade | Strength Level | Typical Uses |

|---|---|---|

| N30 | Low | Crafts, light holding tasks |

| N35–N42 | Medium | Electronics, sensors |

| N45–N52 | High | Motors, magnetic separators |

| N55 | Very High | Advanced industrial uses |

Note: You should always check the grade before you choose a magnet for your project.

When you look at neodymium magnet grades, you will notice numbers and sometimes extra letters. The number tells you the strength of the magnet. For example, N52 means the magnet has a maximum energy product of 52 MGOe, which makes it one of the strongest types you can find. Manufacturers use this system to label magnets during quality control. The letter "N" means neodymium, and the number shows the strength.

Sometimes, you will see extra letters after the number, like "SH" or "UH." These letters tell you about the magnet's temperature resistance. For example, "SH" means the magnet can work at higher temperatures without losing its strength. This helps you pick the right magnet for places that get hot.

The grading system uses an "N" and a number to show strength.

Extra letters after the number show how well the magnet handles heat.

You can use these labels to find the best magnet for your job.

Tip: Always match the magnet grades to your needs for strength and temperature. This helps you get the best results and keeps your equipment safe.

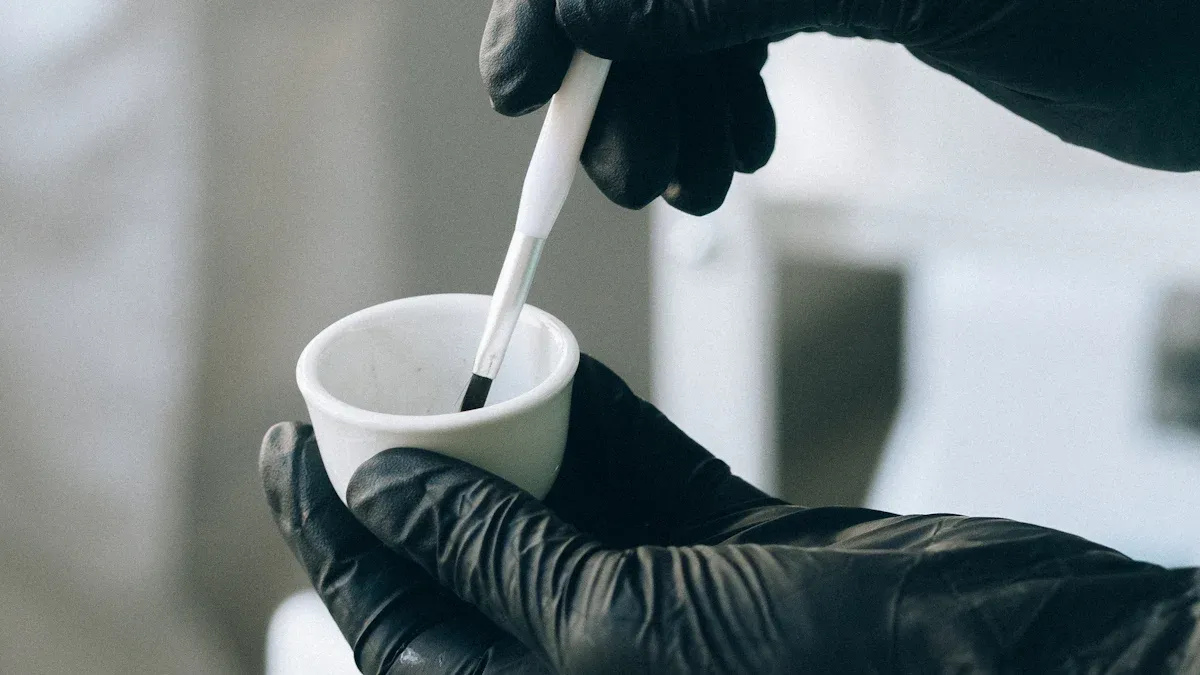

Image Source: pexels

When you measure how strong a neodymium magnet is, you will see two main terms: pull force and gauss. These two measurements help you understand how the magnet works in real life.

Pull force tells you how much weight the magnet can hold when it sticks to a flat, metal surface. You often see this measured in pounds or kilograms.

Gauss measures the magnetic field’s strength. It shows how powerful the magnetic field is at a certain spot near the magnet.

You can use these measurements to compare magnets and choose the right one for your job. Pull force helps you know if the magnet can hold or lift what you need. Gauss helps you see how strong the magnetic field is for tasks like sensors or electronics.

Tip: Always check both pull force and gauss when you pick a neodymium magnet. This gives you a full picture of its strength.

Many things can change how you measure the strength of a neodymium magnet. Temperature is one of the most important factors. When the magnet gets hot, the atoms inside move more, and this can make the magnet weaker. Every neodymium magnet has a maximum temperature it can handle. If you go above this temperature, the magnet can lose its strength forever. Cold temperatures can make the magnet stronger by helping the atoms line up better.

Humidity also plays a big role. If the air is very wet, the magnet can start to rust. Without a good coating, a magnet can lose up to half its strength in humid places. Moisture can damage the magnet and cause it to lose power for good.

Other things like bumps or drops can hurt the magnet. If you store magnets the wrong way, they can also lose strength over time.

Humidity can cause rust and make the magnet weaker.

Without coatings, magnets can lose up to 50% of their strength in wet air.

The Curie temperature is the point where the magnet loses all its power.

If you go above the maximum temperature, the magnet can lose strength forever.

Small losses can happen even below the maximum temperature, but these are usually not permanent.

Note: Always store and use your neodymium magnets in dry, cool places to keep their strength for a long time.

When you pick a neodymium magnet grade, you should think about your job and industry. Every job needs something different from the magnet. You have to match the grade to the strength, heat, size, and price you need. For example, cars need magnets that work in hot places and can handle strong pulls. Electronics need magnets with exact shapes and steady magnetic fields. Medical tools need magnets that are safe and work well.

Here is a table to help you see how to match magnet grades to different applications:

| Criteria | Description |

|---|---|

| Strength | Pick the grade that gives you the magnetic force your application needs. |

| Operating temperature | Make sure the magnet can handle the heat in your application. |

| Size and shape | Choose the magnet grades that fit the space and design of your application. |

| Cost | Higher magnet grades cost more, so balance your budget with your needs. |

Steel factories use strong magnets to lift and sort metal. Electronics companies use medium magnets for things like sensors and speakers. Food factories use special magnets to keep food safe from metal pieces. Every industry has its own needs, so picking the right grade helps you do your job well.

Tip: Always check the grade, strength, and temperature limits before you pick a magnet for your application.

TAIXIONG can help you pick the best magnet grade for your job. You can find many kinds of neodymium magnets in TAIXIONG’s products. The company has strong neodymium magnets, pot magnets, rubber coated magnets, and flexible magnets. These magnets work well in healthcare, cars, and electronics.

TAIXIONG has more than 20 years of experience. The team knows how different jobs use magnet grades. You can ask TAIXIONG for help when you need to pick the right grade. The company helps you match the grade to your job, whether you need strong magnets for metal, exact magnets for electronics, or safe magnets for food and medicine.

High-performance neodymium magnets give strong force for heavy jobs.

Pot magnets are good for holding and mounting things.

Rubber coated magnets protect surfaces and work in wet or gentle places.

Flexible magnets can bend and fit special shapes.

TAIXIONG’s experts listen to what you need. They help you compare magnet grades and pick the best one for your job. You get help from start to finish, so your project goes well.

Note: TAIXIONG’s big product range and deep knowledge make it easy for you to find the right magnet grades for any job.

Image Source: pexels

You should know the dangers before using neodymium magnets. These magnets are very strong and can cause accidents if you are not careful. Neodymium is brittle, so it can break or shatter if you drop or hit it. This can make sharp pieces fly out. High heat can also make the magnet weaker. Always check the highest temperature the magnet can handle before using it. If you keep magnets in very hot or cold places, they can lose strength or become unsafe.

Here is a table that lists the main dangers:

| Risk Type | Description |

|---|---|

| Magnetic Interference | Neodymium magnets can mess up electronics like hard drives and pacemakers. |

| Breakage | The brittle magnet can break and send sharp pieces flying. |

| Jumping | Strong pull can pinch your skin or break fingers. Swallowing magnets is also very dangerous. |

| Flammability | Dust from broken magnets can catch fire if the air is not moving. |

Always wear gloves and eye protection when you use neodymium magnets.

You can stay safe by following these steps:

Wear gloves and safety glasses to protect your hands and eyes.

Keep magnets away from electronics and things that can be damaged.

Store magnets in non-magnetic boxes in a dry, cool place.

Do not drop or hit magnets so they do not break.

Use non-magnetic tools to pull magnets apart.

Handle one magnet at a time to avoid pinching your skin.

Teach kids and coworkers how to use magnets safely.

Get medical help right away if someone swallows a magnet.

You should also keep neodymium magnets in a place that is not too hot or wet. This helps the magnets stay strong and safe for a long time. Always check the highest temperature the magnet can handle before using it in hot places.

Tip: Never drill or cut neodymium. This can make it break or catch fire.

TAIXIONG cares about your safety. The company makes neodymium magnets with safety in mind. TAIXIONG puts coatings on magnets to stop water and damage. The team checks every magnet for strength and heat limits. TAIXIONG also gives tips on how to store and use magnets safely. You can trust TAIXIONG to help you use magnets the right way. The company works hard to make magnets that are safe in hot or cold places and meet strict safety rules.

TAIXIONG helps you use magnets safely and get your work done.

You have learned the main ideas about neodymium magnet strength, grades, and safety. Keep these important things in mind:

N52 is a higher grade and is much stronger. N35 is a lower grade and is good for lighter tasks.

Each neodymium grade handles heat in its own way. This is important for many jobs.

A magnet’s coating helps it last longer in many places.

If you need more help or have questions, TAIXIONG can help you:

| Service Type | Contact Information |

|---|---|

| Phone | +86-021-57599048 / +86-021-57599009 |

| Mobile | +86-13681717549 |

| Yingyun@taixiongmagnet.com | |

| WhatsApp Link | |

| Address | No.334 Xinghuo Road, QianQiao Town, FengXian District, Shanghai, China |

You can also visit the TAIXIONG website. There you will find guides, product pages, and FAQs to learn more about neodymium and magnet safety.

The "N" stands for neodymium. You see it before the number in magnet grades, like N52. This letter helps you know the type of magnet you have.

You can measure strength using pull force or gauss. Pull force shows how much weight the magnet can hold. Gauss tells you the magnetic field strength at the surface.

Yes, they can. High heat, moisture, or physical damage can make magnets weaker. You should store them in cool, dry places to keep them strong.

No, they are not safe for children. Small magnets can cause serious injury if swallowed. Always keep them out of reach of kids.

You find neodymium magnets in electronics, automotive, healthcare, and recycling. These magnets help in speakers, motors, MRI machines, and metal sorting.