Language

Views: 0 Author: Site Editor Publish Time: 2025-12-02 Origin: Site

You want the best neodymium magnets for your needs. You should know which grades and coatings work best. The most common grades are N52, N45, N42, N38, and N35. N52 is known for being very strong. Nickel is the most used coating. It protects against rust and lasts a long time. Polymer and zinc coatings are also used a lot. Picking the right magnet strength and coating for your space helps keep magnets working well. It also makes them last longer.

TAIXIONG gives you high-quality magnets for your industry. When you pick magnets, think about how well they work, how long they last, and how much they cost. This helps you get the best results.

| Key Findings | Description |

|---|---|

| Coating Importance | Coatings help stop rust, which is important for NdFeB magnets because neodymium reacts easily. |

| Durability vs. Cost | Strong coatings can cost more but protect better and last longer. |

Learn about magnet grades such as N35, N42, and N52. Higher grades make magnets stronger. Strong magnets are important for tough jobs.

Pick the best coating for your magnets. Nickel, epoxy, and rubber coatings protect magnets in different ways. These coatings help stop rust and damage.

Think about where you will use the magnet. Magnets outside or in wet places need special coatings. These coatings keep out water and stop corrosion.

Compare cost and how well the magnet works. Stronger magnets like N52 cost more money. They last longer and work better.

Talk to experts like TAIXIONG for advice. Experts help you choose the right magnet for your needs. This makes sure your magnet works well and lasts a long time.

Image Source: pexels

Neodymium magnets have labels like N35, N42, or N52. These labels show the magnet grades. Each grade tells you how strong the magnet is. The number after the "N" means the maximum energy product. This is measured in Mega Gauss Oersteds (MGOe). A bigger number means a stronger magnet. For example, N52 is much stronger than N35.

Here is a simple table to help you see the difference:

| Grade | Maximum Energy Product (MGOe) | Strength Comparison |

|---|---|---|

| N35 | 35 | Weaker than N52 |

| N42 | 42 | Weaker than N52 |

| N52 | 52 | Strongest among N35, N42, and N52 |

TAIXIONG has many magnet grades. You can pick the right strength for your project. Some projects need a gentle hold. Others need the highest pull force.

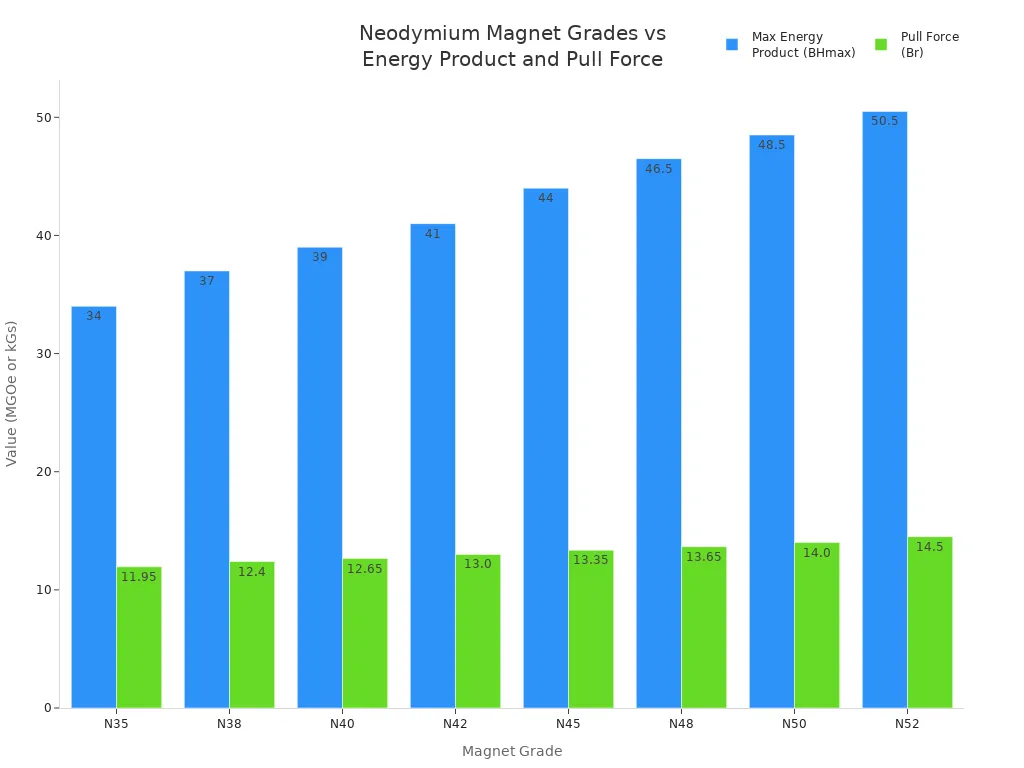

It is good to know how magnet grades compare in strength. The table below shows the maximum energy product and pull force for common neodymium magnets:

| Grade | Maximum Energy Product (BHmax) | Pull Force (Residual Induction Br) |

|---|---|---|

| N35 | 33–35 MGOe | 11.7–12.2 kGs |

| N38 | 36–38 MGOe | 12.2–12.6 kGs |

| N40 | 38–40 MGOe | 12.4–12.9 kGs |

| N42 | 40–42 MGOe | 12.8–13.2 kGs |

| N45 | 43–45 MGOe | 13.2–13.5 kGs |

| N48 | 45–48 MGOe | 13.5–13.8 kGs |

| N50 | 47–50 MGOe | 13.8–14.2 kGs |

| N52 | 49–52 MGOe | 14.3–14.7 kGs |

You can also see the comparison in this chart:

A higher magnet grade gives you more strength and pull force. This is important when you need your magnet to work well.

You want to pick the right magnet grade for your job. Many factories and companies use N40 or N45 neodymium magnets. These grades give a good balance between cost and performance. They work well in sensors, motors, and other machines. If you need more power, you can use N45 to N52. These higher grades are best for strong motors or small devices where space is tight.

TAIXIONG gives these magnet grades to many industries. These include automotive, electronics, and manufacturing. For example, a car factory may use N45 magnets in electric motors. An electronics company may pick N42 magnets for hard disk drives. You can trust TAIXIONG to help you choose the right magnet.

Here is a table that shows how different magnet grades fit different industries:

| Grade | Max Operating Temp | Typical Industries | Common Applications |

|---|---|---|---|

| N35 | 80°C (176°F) | Consumer Electronics | Magnetic toys, closures, displays |

| N42 | 80°C (176°F) | Electronics, Education | Hard disk drives, magnetic clasps |

| N52 | 80°C (176°F) | Industrial, Aerospace | High-performance motors, compact devices |

If you are a hobbyist, first decide what you want your magnet to do. Think about how much weight it needs to hold. Also, think about where you will use it. For small projects, N35 or N42 magnet grades are often enough. If you need more power, try N50 or N52.

Decide what your project needs, like load and place.

Pick a magnet grade that matches your strength and budget.

Choose coatings or grades that last longer if you use magnets outside.

Medical devices need special care. Neodymium magnets are popular because they are strong for their size. Medical makers use them in MRI machines, hearing aids, and surgical tools. These magnets must follow strict safety rules. Some rules are ISO 10993 for biocompatibility and ISO 13485 for quality. TAIXIONG gives magnets that meet these standards. You can use them safely in medical equipment.

| Magnet Type | Key Features | Regulatory Standards |

|---|---|---|

| Neodymium Iron Boron (NdFeB) | Very strong for its size; needs strong coatings for safety. | ISO 10993 (biocompatibility), ISO 13485 (quality management), IEC 60601-1 (safety) |

| Samarium Cobalt (SmCo) | Good at handling heat and resists rust. | ISO 10993, ISO 13485, IEC 60601-1 |

| Ferrite (Ceramic) | Not as strong, but good insulation and cheaper. | ISO 10993, ISO 13485, IEC 60601-1 |

| Bonded Magnets | Can be made into custom shapes for small devices. | ISO 10993, ISO 13485, IEC 60601-1 |

Tip: Always match your magnet grade to your project’s needs. TAIXIONG can help you pick the best option for your industry, hobby, or medical device.

Image Source: pexels

Magnets need protection from rust and damage. The right coating helps them last longer and work better. There are many coatings for neodymium magnets. Each coating gives different benefits. Some coatings stop rust. Others protect the magnet from bumps or scratches.

Here is a table that lists common coatings and what they do:

| Coating Type | Protective Properties |

|---|---|

| Zinc | Corrosion resistant; forms zinc oxide for extra protection. |

| Gold | High corrosion resistance; conductive; used in therapy and water applications. |

| Silver | Good corrosion resistance; biocompatible; used in medical devices. |

| Everlube® | Excellent chemical and corrosion resistance; durable barrier. |

| Teflon® (PTFE) | Highly corrosion resistant; works in harsh environments. |

| Parylene | Superior resistance; improved abrasion resistance; used in electronics and medicine. |

| Nickel (Ni-Cu-Ni) | Excellent protection; good for moist environments; cost-effective. |

| Epoxy | Superior corrosion resistance; impact resistant. |

| Rubber | Good moisture protection; adds grip and cushioning. |

TAIXIONG has many coatings for your magnets. You can pick the best one for your job. This is true if you work in electronics, medicine, or factories.

You should pick a coating that fits where you use the magnet. Some coatings are better for inside. Others protect the magnet outside or in wet places. Nickel coatings are strong against wear and water. Epoxy coatings are good for wet or salty places. Rubber coatings add grip and help outside.

Here is a table to help you choose the right coating for each place:

| Coating Type | Resistance to Moisture | Resistance to Saltwater | Corrosion Resistance |

|---|---|---|---|

| Epoxy | High | High | Very High |

| Rubber | High | High | Moderate |

| Stainless Steel | Moderate | High | High |

| Zinc | Moderate | Moderate | Moderate |

| Nickel | Good | Good | Excellent |

Epoxy coatings keep magnets safe in wet or chemical places.

Rubber coatings are good when you need more grip or shock safety.

Nickel coatings are great for most uses inside.

TAIXIONG helps you pick the right coating for your magnet. This gives you better results and a longer-lasting magnet.

You want your magnet to last a long time. The right coating keeps it safe from rust, scratches, and bumps. Nickel coatings protect well from wear and scratches. Epoxy coatings make a strong shield against salt and water. Zinc coatings are good for outside and make a white layer. Rubber and plastic coatings give extra safety and help with impacts.

You can see how coatings compare in this table:

| Coating Type | Corrosion Resistance | Mechanical Strength | Effectiveness | Notes |

|---|---|---|---|---|

| Nickel | Excellent | Good | High | Three-layered for durability |

| Zinc | Moderate | Lower | Good | Best for outdoor use |

| Epoxy | Superior | Good | Very High | Great for marine settings |

| Rubber | Moderate | Good | Good | Adds grip and shock absorb |

| Teflon | High | Good | High | Seals out moisture |

You can test how strong a coating is with easy tests. The tape test checks if the coating sticks well. The scratch test shows if it can handle scrapes. The impact test checks if it breaks when hit.

Tip: Always pick a coating that fits your place and use. TAIXIONG can help you choose and offers many coatings. This helps your magnet last longer and work better.

You want your magnet to work well for your job. First, think about how much pull force you need. N35 or N42 magnets are good for light holding. If you need a stronger pull, pick N52. The coating is important too. Nickel coatings protect magnets inside buildings. Epoxy coatings help in wet or rough places. Rubber coatings give more grip and cushion. Always choose the right magnet grade and coating for your needs. This helps your magnet work its best.

Tip: Pick the right coated magnet so it lasts longer and keeps its strength.

Magnets can get damaged outside or in wet places. You should use magnets with special coatings for these areas. Epoxy coatings keep magnets safe from rain and salt. Rubber coatings help when there are bumps or shocks. Here are some things to remember for outdoor use:

Rubber coatings help with grip and protect from hits.

Nickel coatings are good inside but need more care outside.

Reports show neodymium magnets in the ocean can lose strength fast if not coated. The table below shows what happens in tough places:

| Evidence Description | Key Findings |

|---|---|

| Corrosion in Marine Environments | Neodymium magnets rust fast in saltwater, with damage in weeks. |

| Environmental Risks | Rust can put bad stuff into the water. |

| Structural Integrity | Hydrogen can make cracks and lower strength. |

| Magnetic Strength Loss | Uncoated magnets can lose up to 5% pull force each year in the ocean. |

You need to think about price and how well the magnet works. Stronger magnets like N52 cost more but pull harder and work better. Lower grades like N35 are cheaper and good for easy jobs. The table below helps you compare:

| Magnet Grade | Cost Difference | Performance Impact |

|---|---|---|

| N35 | Base Price | Normal pull force for simple jobs |

| N52 | 20-30% more | Stronger pull force, better for hard jobs |

You can also try these ideas:

Test different magnet grades to see which works best.

Use simple shapes to save money.

Pick ferrite magnets if you do not need strong pull.

High-grade neodymium magnets cost more because they use rare earths and need careful making.

TAIXIONG gives you many magnets for your job. You can get magnets for separators, conveyors, and bearings. These magnets help keep your machines clean and safe. Magnetic bearings lower rubbing and help machines run well. TAIXIONG magnets work great in fast and clean places.

| Feature | Benefit |

|---|---|

| Magnetic Levitation | No touching, less rubbing |

| High-Speed Movement | Fast moving for your job |

| Clean Operation | Safe for delicate products |

You can trust TAIXIONG for strong and lasting magnets. Each magnet gets checked carefully. TAIXIONG magnets last over 500 hours in salt spray and wet tests. Customers like the quick help and good support. You always get the right magnet for your job.

To choose the right neodymium magnet, follow these steps:

Check where you will use the magnet and what conditions it faces.

Pick a coating that protects against wear and moisture.

Match the grade to your strength and performance needs.

Balance cost with how long you want the magnet to last.

TAIXIONG’s experts can help you find the best solution for your project. Visit their website for guides, product details, and support.

You should choose N52 grade for heavy-duty tasks. This grade gives you the highest strength and pull force. It works well in industrial machines and compact devices.

Epoxy coating protects magnets best in wet environments. It resists water and salt. You can use it for outdoor or marine applications.

You need the strongest rare earth magnets when you want maximum holding power in a small space. These magnets work well in motors, sensors, and scientific equipment.

You can use neodymium magnets for medical devices. Make sure the magnets meet safety standards like ISO 10993 and ISO 13485. TAIXIONG offers magnets for medical use.

You should choose the right coating for your environment. Store magnets in dry places. Avoid dropping or hitting them. TAIXIONG can help you select durable options.