Language

Views: 0 Author: Site Editor Publish Time: 2025-12-08 Origin: Site

Neodymium magnets are strong tools used in many industries. You can find them in small electronics, cars, and wind turbines. Neodymium, iron, and boron make each magnet strong and tough. TAIXIONG is a top company that makes magnets for hard jobs.

The world market for neodymium magnets could be USD 7.30 billion by 2030.

The market may grow 6.7% every year from 2025 to 2030.

You can learn how the mix, making process, and quality checks help magnets stay strong and work well.

Neodymium magnets are made from neodymium, iron, and boron. This mix makes the magnets strong and tough.

Picking the right additives can make magnets work better. Some elements, like dysprosium, help magnets handle heat.

Quality control is very important when making magnets. TAIXIONG checks magnets with strict tests. This makes sure every magnet is high quality.

Good packaging keeps magnets safe when shipped. TAIXIONG uses special materials to protect magnets. This helps magnets stay safe and work well when they arrive.

Knowing how magnets are made helps you choose the right ones. TAIXIONG has many shapes, sizes, and coatings for magnets.

Neodymium magnets are very strong because of what they are made of. Their power comes from a mix of neodymium, iron, and boron. This mix is called neodymium iron boron. It helps the magnet pull hard and last a long time. You can look at the table below to see how much of each element is used:

| Element | Weight Percentage |

|---|---|

| Neodymium (Nd) | 29% - 32% |

| Iron (Fe) | 64.2% - 68.5% |

| Boron (B) | 1.0% - 1.2% |

This mix is the main part of neodymium ndfeb magnets. Getting the right amount of each element is important for strong magnets. TAIXIONG makes sure the mix is just right. These magnets work in motors, sensors, and other machines.

You can make neodymium iron boron magnets better by adding other elements. These extra parts help magnets work in tough places. Here is a table that shows what some additives do:

| Additive | Effect on Performance | Notes |

|---|---|---|

| Boron (B) | Makes the magnet harder and helps it handle heat | Too much boron can make the magnet weaker. |

| Dysprosium (Dy) | Helps magnets work in hot places | Needs to be added carefully. |

| Terbium (Tb) | Helps magnets work in heat like dysprosium | |

| Cobalt (Co) | Helps magnets last longer and not rust | Costs more; must use the right amount. |

| Aluminum (Al) | Makes some magnetic properties better | |

| Praseodymium (Pr) | Can take the place of neodymium and save money | Used in NdPrFeB magnets. |

Magnets with these additives are used in cars, wind turbines, and electronics. TAIXIONG uses gallium to make the magnet stronger against losing its power. Dysprosium and terbium help magnets work in hot places. Praseodymium can be used instead of neodymium to save money but still keep the magnet strong. Cobalt and aluminum help magnets last longer in wet or sour places.

Magnets need to stay strong and last a long time. What they are made of affects how they handle heat, water, and pressure. Here are some things that decide how long magnets will work:

| Factor | Description |

|---|---|

| Thermal Effects | Heat can make magnets weaker. Some types can handle high heat. |

| Corrosion and Oxidation | Water and air can make magnets rusty. Coatings help stop this. |

| Mechanical Stress | Magnets can break if dropped or pressed too hard. |

| External Demagnetizing Fields | Strong magnetic fields can make magnets lose power. |

| Aging | Magnets can get weaker over time, especially with heat or water. |

TAIXIONG puts coatings like NiCuNi, Epoxy, or Zinc on magnets. These coatings protect magnets from rust and damage. You can pick magnets for hot jobs, like motors or generators. TAIXIONG uses fine powders to make magnets better and stronger. This means you get magnets that work well even in hard places.

Tip: When you choose neodymium magnets, look at the grade and coating. This helps you pick the right magnet and makes sure it lasts a long time.

The way neodymium magnets are made, with the right mix and smart additives, helps them work well and last long. TAIXIONG knows how to make magnets you can trust for any job.

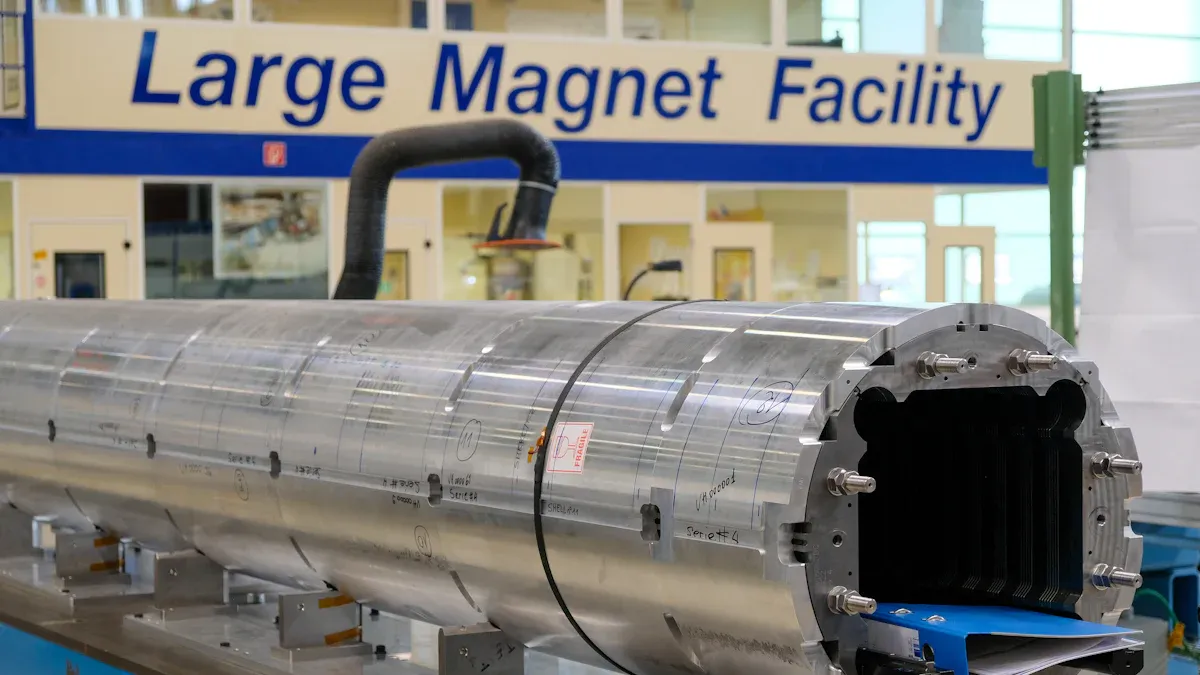

Image Source: unsplash

You can learn how TAIXIONG makes strong neodymium magnets by following careful steps. Every step is important for how well the magnet works and how long it lasts. You get magnets that fit what you need, like sintered neodymium magnets, bonded ndfeb magnets, or special shapes.

The process starts with very pure materials. TAIXIONG uses neodymium, iron, and boron that are very clean. The company checks each batch to make sure the magnets will be strong and last a long time. You can see the purity rules for each material in the table below:

| Material | Purity Requirement |

|---|---|

| Neodymium | Exceeds 99.5% |

| Iron | Ultra-high purity |

| Boron | Ultra-high purity |

TAIXIONG uses its own sintering furnaces and special machines to keep quality high. You get magnets that are the right size and work well. The company also uses coating lines and SPC to check every step. You can see the main quality checks in this table:

| Quality Control Measure | Description |

|---|---|

| In-house sintering furnaces | Control the alloy preparation process |

| Precision machining centers | Ensure tight tolerances (±0.05mm) |

| Multi-layer coating lines | Provide corrosion resistance (e.g., Ni-Cu-Ni) |

| SPC implementation | Monitor and control the manufacturing process |

| Testing procedures | Verify magnetic properties and dimensional accuracy |

| Salt spray testing (ASTM B117) | Assess coating durability |

| Destructive sampling | Analyze internal structure for quality assurance |

Next, you melt the neodymium, iron, and boron together. TAIXIONG melts them in a vacuum furnace at very high heat, about 1500-1600°C. The melted mix is poured onto a fast copper wheel, making thin ribbons. You must control the wheel speed, pressure, heat, and air in the chamber. This makes sure the mix is even and the magnet will be strong.

Melt the NdFeB alloy in a vacuum furnace.

Heat the materials until they are liquid.

Pour the liquid onto a spinning copper wheel to cool fast.

Control all steps to get the best material.

This process helps the grains spread out evenly. You get a magnet that is the same all over. This makes the magnet stronger and more dense. Low-melting alloys help the parts stick together better during sintering.

Now, you grind the ribbons into a fine powder. This step is important for making good magnets. You need small powders for better alignment and stronger magnets. TAIXIONG checks the powder size and shape. You can see how powder size matters in the table below:

| Evidence Description | Key Insight |

|---|---|

| Finer powders improve alignment | Better particle alignment gives optimal magnetic properties |

| Fine-grained structure | Well-distributed Nd-rich phase boosts magnetic performance |

| Presence of pores | Large pores can lower magnetic performance |

There are challenges in grinding and sintering the powder. You need powders with high coercivity and single crystals for the best magnets. TAIXIONG uses advanced methods to solve these problems and make strong ndfeb magnets.

It is hard to sinter and keep the powder good.

You need high coercivity in the materials.

Making single-crystal powders is not easy.

You press the powder into shape using a magnetic field. This lines up the particles and sets the magnet’s strength. TAIXIONG uses different ways to press:

Axial Pressing: The magnetic field goes the same way as the pressing.

Transverse Pressing: The magnetic field goes across the pressing.

Isostatic Pressing: Pressure comes from all sides for better alignment.

The sintering step should make a magnet that is dense and has no big grains. You need the right heat all the time. This stops holes that can cause rust and aging.

You follow these steps:

Get the powder ready and line it up with a magnetic field.

Press the powder into a shape.

Sinter the shape in a safe gas. The magnet gets very dense.

Use liquid phase sintering to help the parts stick without big grains.

When you press, you pack the powder to line up the magnetic parts. This is important for strong sintered magnets. The shape you get is weak but ready for the next step.

You cut and shape the magnet to the right size. TAIXIONG uses grinding, cutting, CNC machines, wire EDM, lapping, and polishing. You get magnets that are the right size and very smooth. You can pick special shapes like disc, ring, block, arc, or other designs.

Grinding shapes the magnet and makes it the right size.

Cutting uses diamond tools for accuracy.

CNC machines make complex shapes and tight sizes.

Wire EDM cuts detailed shapes with high accuracy.

Lapping and polishing make the surface smooth.

You protect the magnet with coatings. TAIXIONG has many choices:

Nickel-Copper-Nickel (Ni-Cu-Ni): Great for stopping rust and looks shiny.

Zinc (Zn): Good for rust and not too expensive.

Epoxy: Strong layer that keeps out water and chemicals.

PTFE: Non-stick and resists chemicals.

Gold (Au): Stops tarnish for electronics.

Rubber: Helps absorb shocks and does not slip.

You can pick the coating that works best for you. TAIXIONG tests the coatings with salt spray and other ways to make sure your magnets last.

Tip: You can make your magnets special by picking the shape, size, coating, and how the magnet is charged. TAIXIONG can make multi-pole rings, axial or diametric magnets, and put them together with metal or plastic.

You get neodymium ndfeb magnets that fit what you want. TAIXIONG’s process makes sure every magnet is strong, lasts long, and works well.

Image Source: unsplash

You want magnets that work well every time. TAIXIONG checks magnets with many tests to make sure they are good. During making, workers test the size, shape, and how strong the magnet is. Each batch gets checked by looking and measuring. TAIXIONG uses special tools for testing magnets.

| Testing Items | Testing Instrument | Purpose of Testing |

|---|---|---|

| Residual magnetism (Br) | Gaussmeter | Measures how strong the magnet is on the surface. |

| Coercivity (Hc) | Coercimeter | Checks how hard it is to make the magnet lose power. |

| Maximum magnetic energy (BHmax) | B-H Curve Tracer | Finds out how much energy the magnet can hold. |

| Surface magnetism | Table Magnetic Distribution Tester | Looks at the magnet’s field in a small spot. |

| Microstructure testing | Scanning Electron Microscope | Finds tiny problems and checks how exact the magnet is. |

| Environmental stability test | Various methods | Tests how magnets work in different places. |

TAIXIONG looks at every batch and measures some magnets for size.

| Type of Check | Frequency | Notes |

|---|---|---|

| Visual Checks | 100% per batch | Done at many steps |

| Dimensional Checks | Sample basis | Only some items per batch |

These checks help you get magnets that work well and are strong.

Magnets must follow important rules. TAIXIONG makes sure magnets meet safety and quality standards. These rules help you use magnets in cars, electronics, and medical tools.

DFARS: Stops buying magnets from some countries for defense.

RoHS: Limits bad chemicals in electronics.

IEC 61000: Sets rules for how magnets work with other electronics.

FCC: Controls how much magnets affect other devices.

Electromagnetic Compatibility Directive (2014/30/EU): Makes sure devices work well in Europe.

IEC 60601-1-2: Sets safety rules for medical tools.

MIL-STD-461: Sets rules for military and space use.

TAIXIONG has RoHS, CE, and ISO certificates. These show magnets are safe and good quality. You can trust TAIXIONG magnets for hard jobs.

Magnets need to arrive safe and ready to use. TAIXIONG packs magnets in special ways to protect them. Small magnets go in rows and get wrapped with paper to stop rust. Big magnets use spacers or hard plastic and go in strong boxes.

| Packaging Method | Description |

|---|---|

| Small Magnets | Rows, paper to stop rust, layers to keep magnets apart. |

| Larger Magnets | Rows with spacers or plastic, packed in strong crates. |

TAIXIONG adds foam and polystyrene to block bumps. Iron plates keep the magnet’s field inside the box. Big magnets travel in wood crates for extra safety. Steel and shield plates help keep magnets safe. TAIXIONG checks the magnet’s power and labels boxes if needed. Magnets stay in place so they do not break.

Note: Good packaging and delivery keep magnets safe and strong when you get them.

TAIXIONG has made neodymium magnets for 20 years. You get strong magnets because they check every step. They control what goes into the magnets and how they are made. Their magnets work well and last a long time. If you learn how neodymium is taken out and how rare earth magnets are made, you can pick better magnets for your projects. TAIXIONG can make magnets for any job you need. You can look at their products or ask them for help to find the right magnet for your work.

You can pick disc, ring, block, or arc shapes. TAIXIONG also makes custom shapes for your project. They use CNC machines to create special designs.

Tip:

NiCuNi is good for most jobs. Epoxy keeps magnets safe in wet places. Zinc is a cheaper choice. You can ask TAIXIONG which coating is best for your needs.

Yes, you can choose axial, diametric, or multi-pole types. TAIXIONG can change the direction for motors, sensors, or other uses.

| Magnet Size | Packaging Method |

|---|---|

| Small | Rows, paper, foam layers |

| Large | Spacers, crates, shields |

TAIXIONG puts magnets in strong boxes and uses shields. This keeps magnets safe while they travel to you.

TAIXIONG magnets are used in cars, electronics, and wind power. They are also in food, medicine, and chemical industries. These magnets help machines work better and keep them safe.