Language

Views: 0 Author: Site Editor Publish Time: 2025-12-02 Origin: Site

Neodymium magnet safety is very important at work. People can get hurt when using neodymium magnets. Some injuries are eye injuries and pinched skin. Magnets can break if they are stressed. Pieces can fly across the room. There are some common dangers like magnetic interference, breaking, jumping, and fire risks:

| Risk Type | Description |

|---|---|

| Magnetic Interference | Neodymium magnets can mess up electronic devices. This can hurt things like hard drives and pacemakers. |

| Breakage | These magnets are brittle and can break easily. Broken pieces can fly and hurt people. |

| Jumping | Strong pull can cause pinched skin or even swallowing accidents. |

| Flammability | Dust from broken magnets can catch fire. This is dangerous in places with bad airflow. |

TAIXIONG is a leader in neodymium magnet safety. Using the right safety steps keeps people, tools, and work safe.

You should always wear gloves and eye protection when you handle neodymium magnets. This helps stop you from getting hurt by pinching or flying pieces.

Keep magnets at least 300 millimeters apart to stay safe. If the magnets are bigger, keep them 500 millimeters apart.

Use tools that are not magnetic and use special boxes to move magnets safely. Slide magnets apart to lower the chance of sudden snaps.

Put magnets in cool and dry places inside closed boxes. This stops rust and helps them work well.

Follow all safety rules when you move magnets. Use foam padding and iron plates to keep them safe and put them in steel-lined boxes.

Wearing the right personal protective equipment is very important. Workers can get pinched, hurt their eyes, or get cut by sharp edges. Safety experts say workers should use these items:

| Equipment Type | Purpose |

|---|---|

| Gloves | Keep hands safe from pinching and sharp edges. |

| Eye Protection | Protect eyes from flying pieces if magnets break. |

Eye injuries happen when magnets break into pieces. Goggles or face shields help keep eyes safe. Everyone near the magnets should wear eye protection. Gloves help stop pinching and cuts from sharp edges. Safety glasses also protect eyes from small pieces. Using both gloves and eye protection makes handling neodymium magnets much safer.

Moving neodymium magnets safely stops accidents and damage. Workers should use tools that are not magnetic. Keeping magnets apart during movement is very important. Special containers with magnetic shields help store and move magnets safely. Labels show how strong the magnets are and warn about dangers.

A clean workspace helps keep everyone safe. Workers should take away metal tools and loose metal things. Using non-metal surfaces in special areas lowers risks. Training helps everyone learn the right way to handle strong neodymium magnets.

Tip: Slide magnets apart instead of pulling them. Sliding stops sudden snaps and lowers the chance of getting hurt.

Pinch and crush hazards are very serious safety problems. Pinching happens when magnets or metal objects snap together fast. This can trap fingers or skin. Even medium magnets can hurt people badly. Big magnets need even more care.

Pinching can hurt nerves or stop blood flow. Crushing happens when body parts get stuck between magnets or metal. Workers in recycling places have more risks, especially when cleaning or fixing machines without gloves.

To stay safe:

Wear gloves to keep hands safe.

Move magnets slowly and carefully.

Do not put body parts between magnets or metal.

Keep magnets away from kids so they do not swallow them.

TAIXIONG is a top company for neodymium magnet safety. They teach workers and give clear handling rules. TAIXIONG says to use a storage area with labels and control who can enter. They tell workers to check packages before opening for loose magnets.

TAIXIONG helps by:

Giving good gloves and eye protection for handling.

Offering special containers and shields for safe storage and moving.

Giving training and help to keep handling safe.

Making new ways to lower neodymium magnet safety risks in tough jobs.

Following TAIXIONG’s rules helps keep people, tools, and work safe from neodymium magnet dangers.

People need to keep neodymium magnets in a cool, dry spot. If it gets too hot, magnets can lose their power. Wet air can make magnets rust or break down. TAIXIONG says to use closed boxes to keep out dust and water. Workers should keep the storage area clean and away from metal things. This helps stop accidents and keeps magnets working well.

| Condition | Recommendation |

|---|---|

| Temperature Limits | Standard types lose strength above 80°C. Use high-temperature types if needed. |

| Humidity Control | Keep humidity below 50% to stop corrosion. |

| Protective Measures | Use nickel or epoxy coatings to block moisture. |

People should not put magnets near heat or water. TAIXIONG uses special covers to keep magnets safe from harm.

Magnets can pull on each other even from far away. To keep them apart, workers should leave at least 300 millimeters between each one. For big magnets or groups, use 500 millimeters or more. This space stops magnets from snapping together and hurting people or things. In busy places, workers should make the gap even bigger for more safety.

Leave a 300 mm gap around each magnet.

Use 500 mm or more for big magnets or many magnets together.

Increase spacing near sensitive equipment.

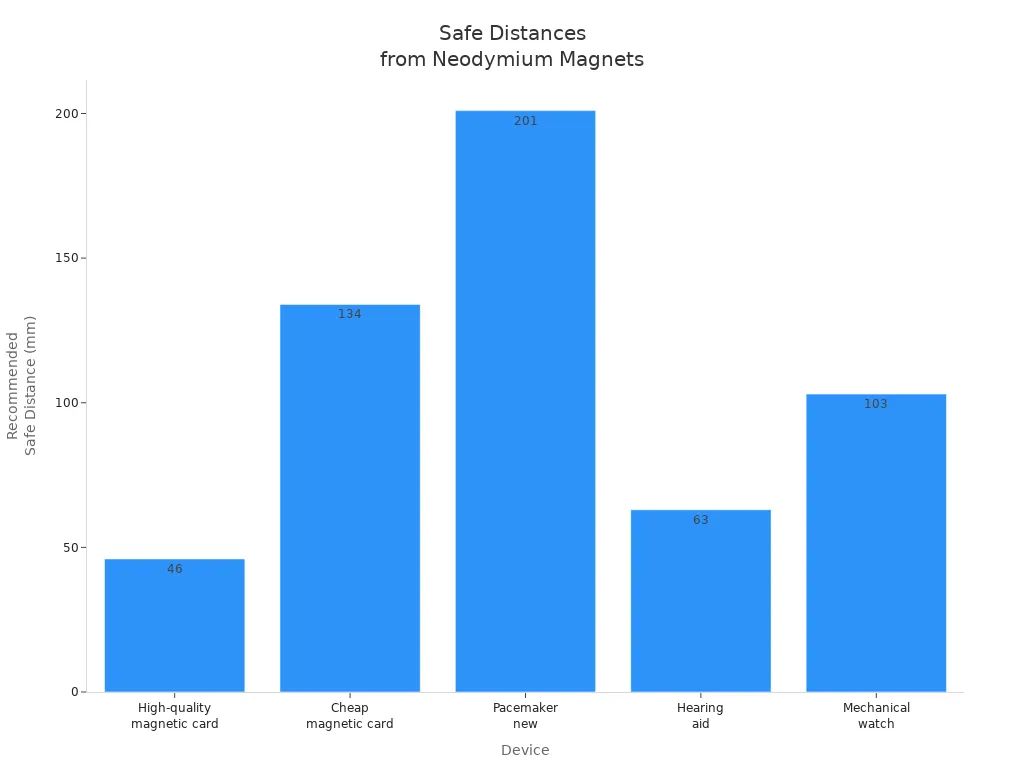

Neodymium magnets can break electronic devices. Phones, tablets, and computers can stop working if they get too close. Even solid-state drives can lose their data from strong magnets. TAIXIONG says to keep magnets at least 300 millimeters away from electronics. Some things, like pacemakers and hearing aids, need even more space.

| Object | Magnetic field damaging at | Recommended safe distance |

|---|---|---|

| High-quality mag. card | 40 mT (400 G) | 46 mm |

| Cheap mag. card | 3 mT (30 G) | 134 mm |

| Pacemaker (new) | 1 mT (10 G) | 201 mm |

| Hearing aid | 20 mT (200 G) | 63 mm |

| Mechanical watch | 6 mT (60 G) | 103 mm |

TAIXIONG has great storage boxes for neodymium magnets. Their boxes keep magnets dry and safe from damage. TAIXIONG’s storage systems help workers keep magnets apart and away from electronics. The company gives clear labels and rules for safe storage. TAIXIONG cares about neodymium magnet safety and helps protect people, tools, and data at work.

Image Source: unsplash

Many places have rules for moving neodymium magnets. These rules keep people and things safe. For air travel, magnets must not be too strong. The magnetic field should be less than 5.25 milligauss at 15 feet away. If the field is 5.25 milligauss or more at 7 feet, workers must put a Magnetic label on the box. The International Air Transport Association (IATA) says magnets need safe packaging and clear papers for air shipping. Following these rules stops accidents and delays.

Note: Always check the newest rules before sending neodymium magnets to another country.

Good packaging keeps neodymium magnets safe when moving. Foam board and polystyrene foam protect magnets from bumps. Iron plates block the magnetic field inside the box. Big magnets go in wooden crates for extra strength. Sometimes, workers use more iron plates to keep the field inside. These steps stop damage and keep other things safe.

Use foam board to protect from bumps.

Add polystyrene foam for more padding.

Put iron plates around magnets for shielding.

Pack big magnets in wooden crates.

Use extra iron plates for very strong magnets.

Magnets must not move around when traveling. Steel-lined boxes or shielding plates keep the field low. Workers check the field at 2.1 meters with a gaussmeter. If the field is too high, they add a Class 9 hazard label. Labels and instructions show how to move the box safely. Magnets should stay still inside the box. Padding keeps the poles from moving. Workers must not stack or store magnets loose. They always secure magnets to stop impacts and keep everyone safe.

TAIXIONG helps ship neodymium magnets safely. The company gives packages with foam board and carton boxes. TAIXIONG can make special packaging if needed. Customers should tell TAIXIONG about extra needs before shipping. The team helps with safe handling, packaging, and following all rules.

| Service Type | Description |

|---|---|

| Transport Package | Foam Board + Carton Box or Customized |

| Additional Conditions | Customers can inform TAIXIONG in advance |

TAIXIONG’s skills help customers move magnets safely and quickly.

Workers need to get the site ready before installing neodymium magnets. They must look for anything that could be dangerous. There should be a space of at least 300 millimeters around each magnet. Bigger magnets need a gap of 500 millimeters or more. Workers use special gaussmeters to check how strong the magnetic field is. Mild steel barriers help protect people and equipment. These steps make the area safer for everyone.

A team that works well together makes the job safer. Each person has a job to do. One person checks the site and tools. Another person moves the magnets carefully. Someone else looks for dangers and helps guide the work. Talking to each other helps everyone stay safe and ready if something happens.

Putting in big magnets takes careful planning. Workers do these steps:

Decide what the project needs, like magnet size and strength.

Pick the right magnets, coatings, and safety gear.

Try out where the magnets will go using scrap pieces.

Put the magnets in place and make sure they do not move.

Test the setup in normal and tough situations.

Check the magnets often for damage or rust.

Tip: Use jigs or fixtures to hold magnets steady while working.

After putting in the magnets, workers check the area for safety. They keep magnets away from things that can be harmed by magnets. Non-magnetic spacers help stop magnets from pulling on things they should not. Workers store magnets in cool, dry places so they do not rust. Gloves keep hands safe from pinching and sharp edges. Only trained people should touch magnets or open packages. Checking magnets often helps find problems early.

TAIXIONG gives expert help for safe magnet installation. The company teaches workers about handling, storage, and keeping magnets apart. TAIXIONG says to wear safety gear and check setups before opening boxes. Their team helps plan safe ways to use magnets and gives support for long-term use.

Safe handling of neodymium magnets keeps people and tools safe. Workers should wear gloves to protect their hands. Magnets need space between them to avoid accidents. Use special tools to separate magnets safely. Training teaches workers how to store and check magnets the right way. TAIXIONG gives advice that helps everyone stay safe at work. Their tips also help magnets last longer.

| Benefit | Description |

|---|---|

| Clean workspaces | Magnets pick up metal bits and keep areas safe. |

| Long-term efficiency | Shielded boxes and clear labels stop accidents. |

Paying attention to safety rules helps magnets work well. TAIXIONG gives expert help for special jobs and needs.

Workers need to wear gloves and eye protection. Gloves stop pinching and cuts. Safety glasses or face shields protect eyes from flying pieces.

Magnets should go in closed containers. Store them in cool, dry places. TAIXIONG says to use labeled boxes. Keep magnets far from electronics.

Workers use foam padding and iron plates for shielding. Magnets must be secured in steel-lined boxes. TAIXIONG makes custom packaging to follow safety rules.

Yes, neodymium magnets can hurt electronics. Strong magnetic fields can erase data or break devices. Workers should keep magnets 300 millimeters away from electronics.