Language

Views: 0 Author: Site Editor Publish Time: 2025-11-24 Origin: Site

Neodymium magnets are the strongest permanent magnets today. Many people and companies pick these magnets. They are very strong, even when small. In 2023, the neodymium magnet market was worth $5.52 billion. The market is still growing. Electronics, cars, and clean energy need these magnets. Asia Pacific has more than 80% of the market. This shows many people use these magnets there. Picking the right magnet material is important for safety. It also matters for how well it works and how much it costs. You should think about strength, how long it lasts, and if it can handle heat. You also need to choose what works best for your use.

Neodymium magnets are the strongest permanent magnets you can get. They are small but can lift heavy things. This makes them great for electronics and motors.

Different magnets have special uses. Ferrite magnets are cheap and do not rust easily. Alnico magnets can handle high heat. Pick the right magnet for your job.

Neodymium magnets can lose power if they get hot. They work best when under 150°C. Think about heat when using them in hot places.

Not all magnets last the same. Neodymium magnets can chip or rust. Ferrite magnets last longer in rough places. Always be careful when you use magnets.

Cost and recycling are important. Neodymium magnets cost more because they use rare stuff. Recycling helps lower harm to the environment.

Image Source: unsplash

Neodymium magnets have the highest strength of all permanent magnets. They are made from neodymium, iron, and boron. Even small neodymium disc magnets can lift heavy things. Many engineers use neodymium disc magnets for strong, small projects.

Neodymium disc magnets are found in electronics, motors, and sensors. Their holding power is very impressive. For example, a neodymium disc magnet as big as a coin can hold a few pounds. This strong power makes them popular in many products and industries.

Note: Neodymium disc magnets can snap together fast. People must be careful to avoid getting hurt.

Neodymium disc magnets are strong because of their dense atomic structure. This structure helps them make a powerful magnetic field. Many people use these magnets when they need strong holding power in a small space.

Other magnets are ferrite, alnico, samarium cobalt, and flexible magnets. Each type has different strength and holding power.

Ferrite magnets: These magnets are cheap and do not rust. Their strength is much lower than neodymium disc magnets. Ferrite magnets are good for fridge magnets and crafts.

Alnico magnets: These magnets can handle high heat. Their holding power is in the middle. Alnico magnets are used in guitar pickups and sensors.

Samarium cobalt magnets: These magnets are strong and resist heat. Their holding power is strong, but less than neodymium disc magnets of the same size.

Flexible magnets: These magnets bend and cut easily. Their strength is the weakest. Flexible magnets are best for labels and light signs.

| Magnet Type | Relative Magnetic Strength | Typical Holding Power | Common Uses |

|---|---|---|---|

| Neodymium disc magnets | Very High | Excellent | Motors, electronics, tools |

| Ferrite magnets | Low | Weak | Crafts, fridge magnets |

| Alnico magnets | Moderate | Moderate | Sensors, pickups |

| Samarium cobalt | High | Strong | Aerospace, medical devices |

| Flexible magnets | Very Low | Very Weak | Labels, displays |

Neodymium disc magnets are the strongest and have the best holding power. Other magnets work well for special jobs, but none are as strong as neodymium disc magnets. When people need a magnet for tough jobs, they often choose neodymium disc magnets because they work so well.

Neodymium magnets are a kind of rare-earth magnet. They are made by mixing neodymium, iron, and boron together. This mix makes them very strong. These magnets can be tiny but still hold heavy things. People use neodymium magnets in electronics, motors, and headphones. They are great when you need a small magnet that is also strong. Their small size and strong pull make them popular in many fields.

Ferrite magnets are also called ceramic magnets. They are made from iron oxide and other metals. These magnets are cheaper than most others. Ferrite magnets do not rust and work well in wet places. People use them for fridge magnets, speakers, and small motors. Ferrite magnets are not as strong as neodymium magnets. But they last a long time.

Alnico magnets have aluminum, nickel, and cobalt in them. These magnets can handle high heat. Alnico magnets keep working even when they get hot. Many guitar pickups and sensors use alnico magnets. They are not the strongest, but they are steady and reliable.

Samarium cobalt magnets are another rare-earth magnet. They are made from samarium and cobalt. These magnets are strong and can take a lot of heat. People use samarium cobalt magnets in planes, medical tools, and hot motors. They do not rust easily and work in tough places. Samarium cobalt magnets cost more than ferrite or alnico magnets. But they work very well and last a long time. They are picked for special jobs where other magnets might not work.

Flexible magnets are made with rubber or plastic and magnetic powder. These magnets can bend and be cut into shapes. They are not very strong, but they are good for labels, signs, and crafts. People use flexible magnets when they need a special shape. They are safe and simple to use.

Tip: Every magnet type is different. Pick the one that fits your job and where you will use it.

Picking a magnet depends on many things. People look at how strong it is, how much it costs, and how long it lasts. They also check if it can handle heat, if it is easy to shape, and what it is used for. This table helps you see how each magnet is different.

| Magnet Type | Strength (Tesla) | Cost | Durability | Temperature Resistance | Machinability | Typical Applications |

|---|---|---|---|---|---|---|

| Neodymium | 1.0–1.4 (Highest) | High | Moderate | Up to 150°C | Difficult (brittle) | Hard drives, electric vehicle motors, MRI |

| Ferrite | 0.2–0.4 (Moderate) | Low | Moderate | Up to 250°C | Easy | Refrigerator magnets, toys, speakers |

| Alnico | 0.7–1.0 (Lower) | Moderate | High | Up to 500°C | Easy | Sensors, guitar pickups, scientific tools |

| Samarium Cobalt | 0.9–1.1 (High) | Very High | Brittle | Up to 300°C | Difficult (brittle) | Aerospace, military, medical devices |

| Flexible Magnets | 0.1–0.2 (Lowest) | Low | Low | N/A | Very Easy | Advertising, magnetic seals, crafts |

Note: The strength numbers show what each magnet can do. Neodymium magnets are the strongest, even when small. Ferrite magnets are cheap and do not rust. Alnico magnets work in hot places and last a long time. Samarium cobalt magnets can handle heat and do not rust, but they break easily. Flexible magnets bend and cut easily, but they are not strong.

Neodymium magnets pull the hardest. They fit in small spaces and power many devices. People use them in motors, hard drives, and MRI machines. These magnets cost more and can break if dropped.

Ferrite magnets are cheap. They last a long time and do not rust. Many people use them in speakers and toys. These magnets are not good for small spaces that need strong pull.

Alnico magnets can take a lot of heat. They keep working for many years. Guitar pickups and sensors use alnico magnets. These magnets are easy to shape and cut.

Samarium cobalt magnets can handle heat and do not rust. They work in hard jobs like planes and medical tools. These magnets cost the most and break if bent or dropped.

Flexible magnets bend and cut into many shapes. They are cheap and good for crafts, labels, and signs. These magnets are not strong and do not last as long.

This table shows each magnet has good and bad points. Neodymium magnets are the strongest. Ferrite and flexible magnets are the cheapest. Alnico and samarium cobalt magnets are best for hot or special jobs. People should pick the magnet that fits their needs.

Neodymium magnets are strong and used in many things. But they do not work as well when they get hot. Most neodymium magnets work best under 150°C. If it gets hotter, they lose strength fast. The Curie temperature is between 310°C and 400°C. At this point, the magnet stops working and loses all its power.

Some things help decide if a neodymium magnet is good for hot jobs:

Curie temperature is when the magnet stops working.

Some neodymium magnets can handle heat better than others.

Some jobs, like in cars or planes, need magnets that work in heat.

Heat can hurt the coating, which can make the magnet weaker.

Tip: Always check the grade and coating before using neodymium magnets in hot places.

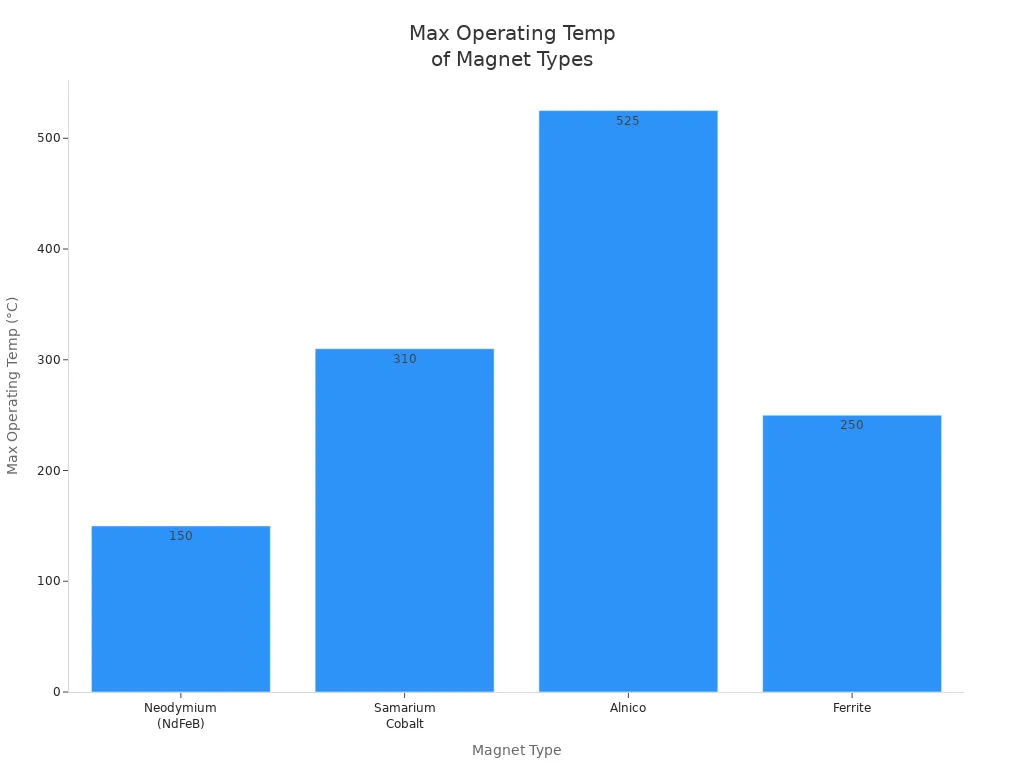

Other magnets act differently when they get hot. Ferrite magnets can work up to 250°C. Alnico magnets can work up to 525°C, which is even hotter. Samarium cobalt magnets can work up to 310°C. These magnets keep their strength better than neodymium magnets when it is hot.

The table below shows the hottest temperatures each magnet can handle:

| Magnet Type | Maximum Operating Temperature | Curie Temperature |

|---|---|---|

| Neodymium (NdFeB) | 150°C | 310-400°C |

| Samarium Cobalt | 310°C | 700-800°C |

| Alnico | 525°C | 800°C |

| Ferrite | 250°C | 450°C |

Ferrite magnets can even get stronger as they get hotter. This helps them keep holding power. Neodymium magnets lose strength faster when they get hot. Alnico and samarium cobalt magnets are better for jobs that need to stay strong in heat.

| Magnet Type | Temperature Resistance | Coercivity Change with Temperature |

|---|---|---|

| Neodymium Magnets | Up to 200 °C | Limited temperature resistance |

| Ferrite Magnets | Up to 300 °C | Increases with temperature |

You should pick a magnet that can handle the heat from your job. Neodymium magnets are good for cool or warm places. For hot places, ferrite, alnico, or samarium cobalt magnets are better and last longer.

Neodymium magnets are very strong. But they are not the toughest. These magnets can crack or chip if dropped. If two magnets snap together, they might break. Their strong pull makes them stick fast. This can cause sharp chips or broken pieces. People need to be careful when using them.

Neodymium magnets can rust if they get wet. Moisture makes them lose power. To stop this, companies add coatings. Some coatings are nickel, zinc, epoxy, gold, silver, rubber, PTFE, and Everlube. Each coating helps in its own way:

Nickel coating stops rust and wear.

Zinc coating keeps out air and is cheap.

Epoxy coating blocks water and chemicals.

Gold and silver coatings protect more and are special.

Rubber and PTFE coatings help with bumps and chemicals.

Everlube coating is great against chemicals and rust, even fuel.

| Coating Type | Properties | Applications |

|---|---|---|

| Nickel | Stops rust and wear | Used a lot for neodymium magnets |

| Zinc | Keeps out air and rust | Cheap choice |

| Epoxy | Blocks water and chemicals | Used in many ways |

| Gold | Great rust protection and safe for people | Special uses |

| Silver | Protects and carries electricity | Used in wires |

| Rubber | Helps with bumps, does not slip | Keeps surfaces safe |

| PTFE | Handles chemicals, slippery | Non-stick jobs |

| Everlube | Best for chemicals and rust | Tough places |

Note: Even with coatings, neodymium magnets can still break if handled roughly.

Other magnets last in different ways. Ferrite magnets do not rust, even without coatings. They work outside and in wet places. Ferrite magnets can take heat and last longer in hard jobs.

Alnico magnets are tough and can take heat up to 500°C. They do not chip as much as neodymium magnets. Samarium cobalt magnets fight rust and heat, but they break easily if dropped. Flexible magnets bend and do not break, but they get weak over time.

| Magnet Type | Strengths | Weaknesses |

|---|---|---|

| Neodymium | Strongest pull, many coating choices | Can rust and chip |

| Ferrite | Cheap, does not rust, takes heat | Not very strong, not pretty |

| Alnico | Tough, takes lots of heat | Medium strength, can lose magnetism |

| Samarium Cobalt | Fights rust and heat | Breaks easy, costs a lot |

| Flexible | Bends, safe for crafts | Weak, does not last long |

People should pick the magnet that fits their job. Neodymium magnets are best for strong pull, but need care and coatings. Ferrite and alnico magnets last longer in tough places. Flexible magnets fit special shapes but do not last long.

Neodymium magnets are more expensive than most other magnets. They cost more because they use rare earth metals. Getting these metals takes a lot of energy. This makes the magnets pricey. The price also changes with size, grade, and coating. Small neodymium magnets for electronics are cheaper than big ones for motors.

How companies make these magnets can hurt the environment. Using new materials has a big impact on nature. Recycling old magnets helps the environment much more.

| Production Method | Environmental Impact |

|---|---|

| Virgin Production | High |

| Magnet-to-Magnet Recycling | Significantly Lower |

Most neodymium magnets are made with new materials. Recycling happens, but not very often. Less than 1% of rare earths get recycled. This makes the magnets expensive and causes worry about waste.

Machining means cutting or shaping magnets into new forms. Some magnets are easy to cut, but others are hard. Ferrite and alnico magnets can be cut and drilled with simple tools. Flexible magnets can bend and be cut with scissors. Neodymium and samarium cobalt magnets are brittle. They can break or chip if not handled gently. You need special tools and safety steps to machine them.

Recycling and throwing away magnets is important too. Here are some facts:

Recycling neodymium and samarium cobalt magnets is possible, but not easy for most companies.

Safe disposal means heating magnets to remove magnetism or using shields so they do not stick to other metals in landfills.

People should think about price, how easy it is to shape, and recycling when picking a magnet. Neodymium magnets are very strong, but they cost more and need careful handling.

Image Source: unsplash

Many factories use magnets every day. Neodymium magnets help machines because they are strong and small. Workers put these magnets in electric motors and generators. They also use them in sensors and sorting machines. Conveyor belts often need magnets too. Safety is very important in these places. Workers wear gloves and eye protection for safety. They keep magnets apart and use tools to move them. Companies store magnets in dry places. They keep them away from sensitive devices. Factories follow rules for shipping and throwing away magnets. They recycle magnets and use heat to remove magnetism.

Tip: Always keep magnets away from kids and people with pacemakers in factories.

People use magnets at home and for fun. Refrigerator magnets, speakers, and headphones all need magnets. Neodymium magnets help small gadgets work better because they are strong. Hobbyists use magnets in model trains and science projects. They also use them in crafts. Flexible magnets are good for making labels and decorations. People should be careful with magnets. They can pinch fingers or break into sharp pieces.

| Magnet Application | Example Products |

|---|---|

| Home Electronics | Speakers, headphones |

| Crafts and Hobbies | Model kits, science sets |

| Organization | Magnetic labels, hooks |

Some magnets are used for special jobs. In hospitals, neodymium magnets help MRI machines take pictures. Magnetic therapy products use these magnets for treatment. Wind turbines and generators use magnets to make clean energy. These magnets are small but very strong. They work even when it gets hot or cold. Their strong pull and small size are good for these uses.

Note: Neodymium magnets can lose power if they get too hot. Do not drill or cut them, because the dust can catch fire.

Each job needs the right magnet. Picking the right magnet helps things work better and last longer.

Neodymium magnets are the strongest for small spaces. Ferrite magnets are good for cheap and outdoor jobs. Alnico magnets can handle high heat and last long. Samarium cobalt magnets do not rust and take heat, but they break fast. Flexible magnets are best for crafts and labels. Every magnet works best for a certain job. The table below shows which magnet is good for each need:

| Factor | Description |

|---|---|

| Operating Temperature | Higher grades can take more heat and lose less power. |

| Demagnetization Risk | High coercivity grades work in strong magnetic fields. |

| Mechanical Needs | Tougher grades are better for impacts or cutting. |

| Budget | Pick what your job really needs to save money. |

Tip: Always think about what your job needs before you pick a magnet.

Neodymium magnets use rare-earth elements. Their atoms are packed in a special way. This makes a strong magnetic field. Even small neodymium magnets can lift heavy things. Their strength comes from how their atoms are lined up.

Neodymium magnets can get weaker if they get too hot or hit hard. Dropping them or heating them too much can make them lose their magnetism forever.

Neodymium magnets are safe if you use them carefully. They can pinch your skin or break if they snap together. Keep them away from kids, pets, and electronics. Always store them in a dry spot.

Ferrite magnets do not rust and can handle water.

They last longer outside than neodymium magnets.

Ferrite magnets are good for wet or damp places.