Language

Views: 0 Author: Site Editor Publish Time: 2026-01-19 Origin: Site

Magnetic assemblies use magnets and other materials. They make magnetic force stronger and improve how things are built. These tools are very important in many industries.

In manufacturing, they help move materials on conveyor belts and robots.

In electronics, they help sensors and motors work.

In medical devices, they help machines like MRI scanners work safely.

| Growth Factor | Description |

|---|---|

| Electric Vehicles | More electric motors and brakes need better assemblies. |

| Smart Devices | More sensors and actuators need accurate magnetic solutions. |

| Industrial Automation | Factories use magnetic assemblies for better safety and efficiency. |

TAIXIONG is a top company for these solutions. Their products help fix common problems in industries and support new ideas.

Magnetic assemblies make things stronger and work better in many industries, like manufacturing, electronics, and medical devices. - Picking the right magnetic assembly means you need to think about the material, how strong it is, if it can handle heat, and if it can resist rust. - TAIXIONG has many types of magnetic assemblies, like pot magnets and special ones made for different needs. - Magnetic assemblies are helpful because they are flexible, work well, and can be used again, so they save money for companies. - Safety is very important when using magnetic assemblies; use them with care to stop injuries and throw them away the right way to keep the environment safe.

Magnetic assemblies are tools that use magnets and other materials together. This makes the magnetic force stronger and more focused. Many industries use these assemblies to hold, lift, or move things safely and easily. A magnetic assembly has a magnet and a housing made from materials that are not magnetic. The housing keeps the magnet safe and helps the assembly work better.

TAIXIONG has made magnetic assemblies for over 20 years. They use new technology and check quality very carefully. TAIXIONG has important certificates like ISO9001:2008 and TS16949. Their products go to customers in more than 50 countries. Many companies trust TAIXIONG for good and dependable magnetic solutions.

A magnetic assembly usually has two main parts:

The magnet alloy is the core. It is very strong and gives the assembly its power.

Non-magnetic materials make the housing and other parts. These are easy to shape and can add special features. They also keep the magnet safe and help focus the magnetic force.

The materials you pick change how the assembly works. Neodymium-iron-boron magnets are very strong and exact. Samarium cobalt magnets work well in high heat and do not rust. Ferrite magnets cost less and are used in many things. Alnico magnets are good for hot places. Flexible rubber magnets are used when the assembly needs to bend.

| Material Type | Description |

|---|---|

| Neodymium-Iron-Boron | High-performance rare-earth magnets known for strong magnetic energy and precise magnetization. |

| Samarium Cobalt | Offers high-temperature stability and corrosion resistance. |

| Ferrite (Ceramic Iron) | Cost-effective and widely used in various applications. |

| Alnico | Known for high-temperature performance and stability. |

| Flexible Rubber | Contains ferrite or NdFeB powder, used in applications requiring flexibility. |

Magnetic assemblies use magnets and a housing to work better. The housing points the magnetic field to the right spot. This makes the pull force stronger. Steel plates or pole pieces help guide the magnetic lines. This design keeps the magnet from breaking and losing power.

The parts inside a magnetic assembly work together in special ways:

| Mechanism | Description |

|---|---|

| Magnetic Dipole Interactions | Particles become magnetized and align due to dipole-dipole interactions, forming chain-like structures in a uniform magnetic field. |

| External Magnetic Fields | A uniform field induces a localized high gradient field, focusing particles for assembly. |

| Repulsive Forces | Particles maintain spacing due to repulsive dipole-dipole forces once they reach the substrate. |

The assembly process can quickly pack layers of particles close together.

Chains of particles line up with the magnetic field.

Repulsive forces keep the particles spaced out, often in rings.

Magnetic assemblies are checked for quality and safety. Common tests are pull force tests, gauss meter checks, and looking for problems. These tests make sure the assemblies are strong and safe for many uses.

Tip: Pick the right magnetic assembly for your job. Think about how strong it needs to be, where it will be used, and the size of the things it will move or hold.

Image Source: pexels

TAIXIONG makes many kinds of magnetic assemblies for different jobs. Each kind has its own features and uses. The company sells both regular magnetic assemblies and custom ones for special needs.

| Product Type | Features | Applications |

|---|---|---|

| Pot Magnets | Strong holding, steel shell, many sizes | Lifting, holding, assembly, electronics |

| Magnetic Hooks | Easy to attach, reusable, strong pull force | Hanging tools, displays, storage |

| Magnetic Bases | Stable support, different strengths and models | Sensor mounts, machinery, conveyor systems |

| Neodymium Magnetic Assemblies | High power, compact size | Motors, wind turbines, electronics |

| Ceramic Magnetic Assemblies | Cost-effective, good for high temperatures | Industrial, educational, and consumer uses |

| Custom Magnetic Assembly Solutions | Tailored size, shape, strength, and coating | Robotics, security, manufacturing |

Pot magnets are a favorite product from TAIXIONG. They have a steel shell that makes them hold things better. Pot magnets come in many sizes like D10, D12, D16, and up to D120. Some have outside threads, inside threads, countersunk holes, or through holes. This helps people use them in many ways.

Pot magnets are found in computer hard disks and cassette recorders. They are also in e-cigarette switches, door locks, and phone speakers. Factories use them to lift and hold metal parts. Their strong holding power makes them useful in lots of places.

| Feature | Details |

|---|---|

| Material | NdFeB + Steel Shell |

| Size Options | D10, D12, D16, D20, D25, D32, D36, D42, D48, D55, D60, D70, D75, D80, D90, D120 |

| Coating Options | Zinc, Ni-Cu-Ni, Cu, Au, Ni |

| Applications | Electronics, machinery, assembly lines |

Tip: Pot magnets are great when you need to hold or lift metal objects safely.

Magnetic hooks are simple tools that use magnets to hang things. TAIXIONG makes these hooks easy to use and strong. You can stick them to metal and move them when you want. Magnetic hooks are good for hanging tools, kitchen items, or store displays.

People use magnetic hooks at home, in offices, and in factories. They help keep spaces neat and save room. The hooks can hold different weights based on their size and strength.

Magnetic hooks can be used again and again without screws or nails.

They work well on fridges, lockers, and metal shelves.

Magnetic bases hold tools and equipment steady. TAIXIONG has many models with different strengths. The base model uses N35 magnets for light jobs like holding sensors. The advanced model uses N42 magnets for medium jobs like conveyor systems. The pro model uses N52 magnets for heavy machines like electric vehicle motors.

| Model | Strength | Use Case |

|---|---|---|

| Base Model | N35 | Light industrial use (sensor assemblies) |

| Advanced Model | N42 | Conveyor systems, mid-tier applications |

| Pro Model | N52 | Heavy-duty machinery, electric vehicles |

Magnetic bases are important in factories and labs. They keep machines safe and steady. Many people pick ceramic magnetic assemblies for these bases because they work well in heat and cost less.

TAIXIONG knows some jobs need special magnetic assemblies. The company lets customers pick the size, shape, strength, coating, and magnetization direction. This helps make the perfect assembly for each job.

Many industries want custom magnetic assemblies. Robotics companies need special shapes and strengths. Security companies want magnets with special coatings. Manufacturing plants often need custom designs for their machines.

| Customization Options | Industries Requesting Custom Designs |

|---|---|

| Magnet size | Robotics |

| Magnet shape | Security |

| Magnet strength | Manufacturing |

| Coating | |

| Magnetization direction |

TAIXIONG works with customers to design and build the right assembly. They use both neodymium magnetic assemblies and ceramic magnetic assemblies for custom projects. This makes sure each job gets the best results.

Note: Custom magnetic assemblies can fix problems that regular products cannot solve.

Image Source: unsplash

Magnetic assemblies are used in many industries. These tools use a magnetic field to move, hold, or separate things. TAIXIONG makes solutions that help factories, businesses, and people work safely and better.

Factories and plants use magnetic assemblies in lots of ways. They lift heavy steel parts and sort materials. They also help machines work well. Magnetic separators are very important in these places. They take out unwanted metal from products. This keeps food, medicine, and other goods safe. In the steel industry, magnetic separators sort scrap and protect machines. The automotive industry uses magnetic assemblies in brakes, steering, and latches. Medical device makers use them in MRI machines and surgery tools. The table below shows how each industry uses them:

| Industrial Sector | Common Applications |

|---|---|

| Consumer Goods | Magnetic knife racks, refrigerator door closures, magnetic phone holders |

| Construction | Lifters, fasteners, alignment tools for material placement and fixing |

| Automotive Industry | Anti-lock braking systems, power steering, electronic latching mechanisms |

| Medical Devices | MRI machines, surgical instruments, implants |

| Renewable Energy | Wind turbines, solar panels for energy efficiency and performance |

| Retail and Display | Shop fittings, shelves, displays, and signs for efficient layout |

| Aerospace and Defense | Navigation, communication, and security systems under high pressure |

Industry 4.0 is changing how factories use magnetic assemblies. Digital tools help companies work faster and make better things. More factories now use magnetic separators for better quality and safety.

Magnetic separators are important for keeping products safe and machines working well in many industries.

Magnetic assemblies are also in everyday items. Businesses use them in displays, shelves, and shop setups. People see them in kitchen racks, phone holders, and name badge clips. Magnetic separators help keep food and medicine safe from metal bits. The table below lists some common products:

| Product Type |

|---|

| Magnetic Chucks |

| Magnetic Welding Holder |

| Round Base Magnets |

| Magnetic Sweepers |

| Magnetic Name Badge Fasteners |

| Magnetic Clips |

| Powerful Magnetic Tool Holder |

| Pot magnets or other shapes for holding |

| Permanent Magnetic Filter |

| Permanent Magnetic Lifter |

| Rotors which may include sleeves |

| Dynamically balanced Rotors |

| Eddy current rolls |

| Pump couplings |

| Reprographic rolls for toner systems |

| Latch assemblies |

| Voice-coil assemblies |

| Beam focusing assemblies |

| NMR assemblies |

Magnetic separators are used in many of these products to make them safer and work better.

TAIXIONG makes special magnetic assemblies for different needs. The company uses Halbach arrays to make magnetic levitation systems and brushless motors stronger and better. These arrays help robots, electric cars, and medical machines run with less friction. TAIXIONG also makes magnetic separators and conveyors with Halbach arrays for factories. These machines help sort metals in steel, food, and electronics plants. Halbach arrays are used in audio devices for better sound and in medical imaging for steady magnetic fields. This design is also used in motors and particle accelerators to save energy.

TAIXIONG’s magnetic separators help companies follow strict safety and quality rules. These solutions help new industries that need advanced technology. The market for magnetic assemblies is growing quickly because of electric cars, renewable energy, and new electronics.

TAIXIONG’s new ideas help businesses solve hard problems with magnetic separators and advanced assemblies.

Magnetic assemblies have many good points compared to old ways of holding things. They help people work faster and safer in lots of jobs. Here are some main benefits:

Flexibility: Workers can take off and move magnetic assemblies fast. In shipbuilding, this is quicker than welding.

Efficiency: Magnetic solutions let workers get to important parts easily. In wind power, workers can reach electronics without breaking anything.

No drilling or glue is needed, so surfaces stay safe.

Reusability: Magnetic assemblies can be used many times.

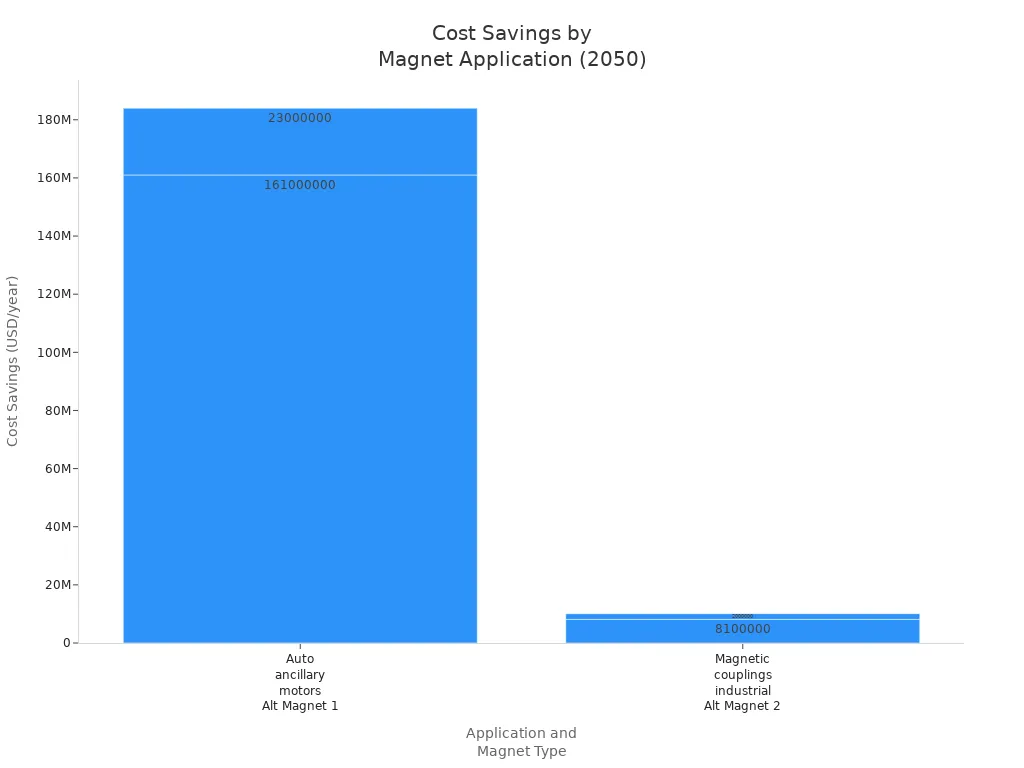

The table below shows how much money companies save by using magnetic assemblies in different areas:

| Application Type | Magnet Type | Cost Savings (USD/year) | Year |

|---|---|---|---|

| Automotive ancillary motors and sensors | Alternative Magnet 1 | 161 million | 2050 |

| Automotive ancillary motors and sensors | Alternative Magnet 1 | 23 million | 2050 |

| Magnetic couplings for industrial and energy applications | Alternative Magnet 2 | 8.1 million | 2050 |

| Magnetic couplings for industrial and energy applications | Alternative Magnet 2 | 2 million | 2050 |

Picking the right magnetic assembly keeps things safe and working well. Think about these things:

Material selection: Choose a magnet that is strong and lasts long.

Magnetic field strength: Figure out how much force you need.

Temperature stability: Make sure the magnet works in hot places.

Corrosion resistance: Use coatings if the area is rough.

Mechanical stability: Check if the assembly can handle being pushed or pulled.

Tip: Always think about where you will use the magnet, what it will hold, and how hot it will get.

Safety matters a lot when using magnetic assemblies. Strong magnets can pinch fingers or hurt people if not used carefully. Magnets can break if dropped, which might hurt eyes. Keep magnets away from electronics so you do not lose data. Heavy assemblies should be held down so they do not move in earthquakes. Fire safety is important, so keep a Class C extinguisher nearby.

Caring for the environment is important too. Throw away and recycle magnetic assemblies the right way to stop pollution. Some rules, like ISO 9001 and CPSC, help keep people safe and protect nature.

| Standard/Rule | Description |

|---|---|

| CPSC Safety Standard for Magnets | Makes sure magnets for kids are safe. |

| Environmental Assessment Regulations | Tells when to check for environmental problems. |

| Aerospace Standards (AS9100D, ISO 9001) | Sets high rules for safety and quality. |

Magnetic assemblies are important in many jobs. They are used in factories and in strong electric motors. TAIXIONG is known for making new and better magnetic assemblies:

They are a top company in the Brazil Printable Flexible Magnets Market.

Big companies around the world trust them for good products.

| Feature | Description |

|---|---|

| Magnetic Strength | N52 grade is 23.8% stronger than N42 for tough jobs. |

| Precision Tolerance | ±3% tolerance helps parts fit right in machines. |

| Environmental Compliance | EPR rules are followed and packaging is good for the earth. |

You can learn more about TAIXIONG’s products at shtaixiongmagnet.com.

Halbach arrays use magnets in a special pattern. This makes one side have a strong magnetic field. The other side has a weak field. Halbach arrays help motors, sensors, and magnetic couplings work better.

Halbach arrays point the magnetic field where it is needed. This helps magnetic couplings move force more easily. Magnetic couplings with halbach arrays waste less energy and are safer for pumps and mixers.

Halbach arrays are in electric motors, wind turbines, and maglev trains. Magnetic couplings are used in pumps, mixers, and medical machines. Halbach arrays make these magnetic couplings stronger and more dependable.

Halbach arrays give magnetic couplings more turning power and less shaking. They also let magnetic couplings work without touching. This means machines last longer and do not wear out as fast.

TAIXIONG makes special halbach arrays for different jobs. The company also builds magnetic couplings for many kinds of work. TAIXIONG uses halbach arrays to make magnetic couplings work better in new machines.